Bigfoot’s Year in Review: Celebrating Growth, Retirements, and Community Spirit” on Bigfoot Crane’s website reflects on the company’s significant accomplishments in 2023. It highlights their expansion and milestones, including the retirement of key team members and their active involvement in community projects. The post encapsulates a year marked by both growth and transition, emphasizing Bigfoot Crane’s commitment to maintaining strong community ties and delivering top-quality service in the construction industry.

This Year, You’re Our Valentine! Have you ever struggled to find crane-specific Valentine’s Day cards for your significant other? Or just to share with your friends? Well this year, Bigfoot wants to give back with a fun & free set of downloadable and printable valentines…

We decided to share this post for two reasons:

First, it’s thesaurus day! Never knew it was a day and we want to share the meaning and explanation of a word “integrity” (which is one of our Core Values at Bigfoot). Second, we found this amazing article by the Smart Company based in Australia. For us at Bigfoot…

We celebrate the women who have worked with Bigfoot and who have demonstrated a strong work ethic, great skills, and grit. On the right in the photo above is Safety Officer, Jen Mutas (In Part 1, we interviewed the woman on the left, Sandra Allard, Crane Technician). We sat down…

“We had a concrete pour scheduled for Friday before the long weekend,” said Justin Tanguay, of DJM Contracting in Rossland, B.C., “but our crane was down.”

Justin and his team were well aware that concrete was in high demand at the time. So, rescheduling a pour could completely mess up project planning. “There was something wrong with the slew motor on our…

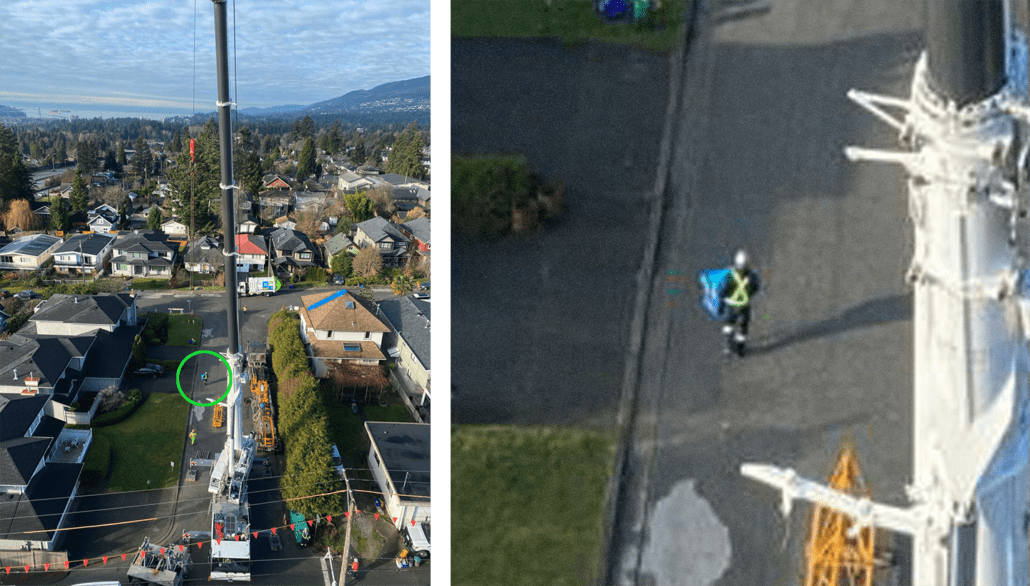

When we say we support the community we live in, we mean it!

Since this North Vancouver street was closed for the mobilization of our San Marco SMT 460 unit, our lead technician James Fujita took the initiative to make sure recycling day wasn’t missed. Living out our values by taking care of our neighbours is Legendary Service, thank you James!

Photo credit: Bigfoot Technician, Sandra Allard

Bigfoot is now proudly represented in Watson Lake, Yukon Territory (YT)’s Sign Post Forest. The landmark is located at Kilometer 980 of the Alaska Highway and has collected over 77,000 signs form around the world. The Sign Post Forest originated in 1942, when recovering U.S. soldier Carl K. Lindley was repairing the directional signs on the highway and decided to add one pointing to his hometown of Danville, Illinois. Since then, visitors from all over the world have brought signs that are significant to them to add to the forest, including our own Ralf Notheis.

When he’s not running Bigfoot’s Crane and Hoist Academy, Ralf is a motorcycle enthusiast. He’s done several solo long-distance trips, and last summer took his longest trip to date yet Tuktoyaktuk, YT, clocking in at about 10,000km. He brought one of Bigfoot’s signs with him to hang in the Sign Post Forest, so we sat down with him to hear more about his trip and what taking a Bigfoot sign means to him.

Bigfoot’s Ralf Notheis in the Arctic Circle

- How long was the entire trip?

I was gone for 13 days. The first few days I was riding pretty hard because I just wanted to get up to the Yukon, and then really take my time from there. - What were the unique challenges of this trip? What made it interesting?

The weather and the clay roads were definitely a challenge. From Dawson City to Tuktoyaktuk is 1,000km of loose gravel and clay; it’s like riding on grease and many people on 2 wheels end up getting flown out from bad crashes. The Robert Campbell Highway from Watson Lake was also really challenging, and a lot of people told me not to do it. There’s only one place to fuel up on that road, but I had just enough gas to get to that station, fuel up, and keep going.I left equipped with a sensible plan and great gear that includes my BMW motorcycle. I was happy to finally drink the Sourtoe Cocktail in Dawson City, along with riding the Dempster Hwy to the Arctic Ocean, it’s been on my to-do list for a long time. If you don’t know what the Sourtoe Cocktail is, click here to learn about this true Candian tradition.

Drinking the Sour Toe Cocktail in Dawson City

- Biking is a big passion of yours. How many trips like this have you taken by yourself?

Tuktoyaktuk was for sure the longest one but I’ve been all over BC, Alberta and through the Western United States. I plan to be in Ushuaia, Argentina in 2023 for my 50th Birthday and ride home from there. - How did you find out about the Sign Post Forest?

I was researching the places I had planned on camping and stumbled across the story about it. Watson Lake, YT is not famous for too many things but the history of this landmark is pretty amazing. - What made you want to put a sign up there?

I think it’s great advertising since thousands of people visit this site annually from all over the world and I didn’t see even one other sign from a competitor.

Ralf’s BMW bike with the Bigfoot sign safely packed

- Tell me about the sign you put up there. How big was it?

It had about an 18 inch diameter and I was able to wrap it and tuck it between my luggage. We’ve had this sign laying in the operations office since I started in 2015 so it was finally put to good use. I got there at night and camped nearby so I just walked over with the sign. It took me almost an hour to find a good spot for it but I’m really happy with where it is, I think it looks really cool. - Why did you decide to take one of Bigfoot’s signs up there and not one from your hometown or an old motorcycle plate?

The Bigfoot logo is way cooler and more personal to me than any other sign I can think of. Sure, I could have taken any other random sign up with me, but the Bigfoot branding just looks so cool! My only concern is that it’s so nice that someone will steal it!

Ralf at his destination: Tuktoyaktuk, YT

The tenacity and dedication that Ralf needed to complete this trip to the Arctic Circle are the same values that drive Bigfoot’s Crane and Hoist Academy and have earned it awards across North America. Click here to discover how combining industry-leading practices with lived-out values make our academy the premier choice for crane and hoist operation training.

If you’re going to work with tower cranes, you better know your hand signals. Clear communication is essential for staying safe on the job site.

A crane operator should always use a signaler, and they should communicate according to the established code of signals. Hand signals are preferred and commonly used. In certain cases, a signaler may be required by law, especially if the operator’s view of the intended path of travel is obstructed in any way.

Here are six essential rules for crane operators and signalers:

- Only a qualified person can be a signaler. They must be trained to give hand signals to a crane operator.

- Only one designated signaler should be assigned for each crane operation. If one signaler ever needs to be replaced by another, the one in charge should wear a clearly visible badge of authority. There should never be two active signalers.

- The crane signaler must be in clear view of the crane operator.

- The crane signaler must have a clear view of the load.

- The crane operator and signaler must both keep other persons outside of the crane operating area and never direct a load over a person.

- A crane operator must obey STOP signals no matter who gives it.

Importantly, the Occupational Safety and Health Administration requires that anyone designated as a signal person must meet certain qualifications and be evaluated by a qualified individual. These regulations, in addition to a commitment to standardized signals, have helped reshape the landscape of crane safety, with crane-related deaths falling to their lowest recorded level in 2017 according to the Bureau of Labor Statistics.

Below, we have a visual guide to basic crane hand signals, including a few signals that are particular to telescopic, crawler and tower cranes. In any case, crane hand signals are an essential part of operating a crane, whether using a small carry deck crane or a larger all-terrain crane. These basic signals are even used with the largest cranes in the world. Some crane rentals also include operators and a signal person in the cost.

Download our new “Tower Crane Hand Signals” chart here: Bigfoot Hand Signals

Working at Height in the Spring: 10 Ways to Stay Safe

Written by: Jen Adams

Key Takeaway: Be prepared for unpredictable spring weather by keeping the job-site clean,

planning for the forecasted weather, using the right PPE, and taking thorough

safety precautions.

Temperatures may be rising, but spring brings its own set of risks (and borrows some from

winter) that need to be taken seriously. Keep these best practices in mind while you’re working

at height this season to stay safe while enjoying the breeze.

1. Always check the weather.

The only thing consistent about spring weather is that it changes consistently. Be prepared for

the heat or cold by checking the weather ahead of time and plan accordingly, and always be

prepared for sudden changes that could occur.

2. Complete thorough safety checks on all large equipment.

With inconsistent weather comes loose earth, mud that gets everywhere, and a higher risk

of rust when equipment is repeatedly soaked and left to dry. Always make sure to check

equipment and machinery before using it and stay up to date on safety regulations by

checking WorkSafeBC.com and using tools like Bigfoot’s Crane Academy.

3. Secure your materials.

High winds can pick up quickly in the spring and are often stronger the higher you work, as the

site is usually more exposed. Make sure the materials you are working with are secure at all

times to avoid injuries or falls from loose materials or objects blowing around.

4. Avoid using power tools in rainy or wet conditions.

Water is an excellent conductor of electricity. By using power tools in the rain or wet after a

rain, you not only run the risk of damaging your tools, but risk electric shock or electrocution if

any wires become exposed while you work. Play it safe and use hand tools where possible or

set up cover over your work area to keep the area dry.

5. Be wary of thunder and lightning storms.

Spring storms are especially dangerous to those working at heights, as lightning is drawn to

metal and tall structures. Monitor the weather report, be aware of your environment, and if the

weather looks dicey, don’t risk working in a storm.

6. Give yourself some traction.

Slipping is always a risk when working on the job-site but becomes even more so when working at

height on wet surfaces. Wear boots and gloves that fit well (make sure they are tight enough that

they can’t slip off, but not so tight as to cut off circulation) and have a lot of traction and grip to

prevent accidents.

7. Always wear appropriate fall PPE, even if working at a lower height.

Most fall-related accidents occur at 30 ft. or less because people view lower heights as less

dangerous, but it takes very little height for a fall to cause injury or even death. Height should be

treated seriously and with caution in any season, but mud and rain make it especially important

to utilize fall PPE in the spring.

8. Let your fall PPE dry naturally before its next use.

Drying equipment with an electric dryer or heater can weaken or melt the material, ruining the

equipment and putting its user at risk. Blot your equipment with towels and hang it up to dry

completely on its own whenever it gets wet, and always check it carefully before each use.

9. Dress warmly enough, and cool enough.

Spring weather may feel warm compared to winter, but its unpredictable nature means that

temperatures can drop to hazardous temperatures, especially when coupled with consistent

cold rains. Dress in layers to ensure you can always keep up with whatever cold or heat the day

throws at you.

10. Train staff to identify weather-based illnesses.

Heat and cold stress occur when the body either warms up faster than it can cool (resulting in

heat exhaustion or sunstroke) or cools down faster than it can warm up (resulting in frostbite

or hypothermia). While they happen more often in summer and winter, they can also strike in

temperatures that don’t seem very extreme. People working at heights can also be at a higher

risk as they tend to be more exposed to the elements. Make sure there are staff on site who are

trained to recognize and treat signs of heat and cold illnesses.

Click here to download: Working at Height in the Spring: 10 Ways to Stay Safe

Receive Industry Updates

Contact

Bigfoot Crane Company Inc.

TSBC License: #LED0205236

2170 Carpenter Street

Abbotsford, BC V2T 6B4

Toll free:

Local:

Fax:

Email:

Photo courtesy of Sandra Allard

Photo courtesy of Sandra Allard