Reliable wind measurement plays a quiet but powerful role across construction, transportation, agriculture, and weather forecasting. When wind conditions shift, the risks and outcomes can change just as quickly, especially in high-stakes environments like crane operations, flight planning, or storm tracking. Instead of relying on instinct or visual clues, professionals across industries use wind-measuring tools to stay informed and ready.

Anemometers provide accurate, real-time data that helps turn unpredictable air movement into useful numbers. They measure wind speed and, in many cases, direction, giving teams the information they need to work smarter and safer. Whether mounted on a job site, used in a weather station, or carried in the field, anemometers have become standard tools for those who need to work with the wind rather than against it.

This article explains what anemometers are, how they function, where they’re used, and why they’ve become so important in everyday decisions.

Definition: What Is an Anemometer?

An anemometer is a device used to measure wind speed. Some models also track wind direction. These instruments are used in construction, aviation, meteorology, agriculture, and even by outdoor hobbyists. Wherever wind matters, an anemometer offers clear, measurable data instead of guesswork.

Understanding why we measure wind helps explain how people use that information to make better decisions. Wind affects safety, comfort, and planning. Measuring it helps people make better decisions. Anemometers work by detecting air movement and translating that into numbers. The science behind measuring wind lies in how these tools sense air movement and translate it into numbers. Different designs do this in different ways, depending on the environment and level of accuracy needed.

Cup Anemometers

This is one of the most recognizable types. It uses three or four small cups mounted on arms. As wind blows, the cups spin. The speed of rotation indicates how fast the wind is moving. These are common on rooftops and fixed weather stations.

Vane Anemometers

A vane anemometer looks like a small windmill. It has a fan blade that spins in response to airflow. Many handheld wind meters use this design. When paired with a wind vane, it can also show wind direction. This type is popular with drone operators and HVAC technicians.

Hot-Wire Anemometers

This type uses a very fine wire that is heated with electricity. When wind passes over the wire, it cools down. The rate of cooling shows how fast the wind is blowing. These are mostly used indoors or in lab testing, including airflow studies in vents and ducts.

Ultrasonic Anemometers

This design has no moving parts. It sends sound waves back and forth between sensors. When wind passes through, it slightly changes the time the sound takes to travel. These differences help calculate both wind speed and direction. Ultrasonic models are often used where reliability and low maintenance are priorities.

Pitot Tube (Pressure-Based) Anemometers

Pitot tubes measure wind using air pressure. They detect the difference between still air pressure and the pressure created when air flows into the tube. They are mostly used in aircraft and wind tunnel experiments.

Why We Measure Wind

Wind has a direct impact on safety, planning, and performance. It affects how structures respond, how machines behave, and how people prepare for changing conditions. The purpose of an anemometer is to provide accurate readings of wind speed and, often, direction, so teams can work with confidence.

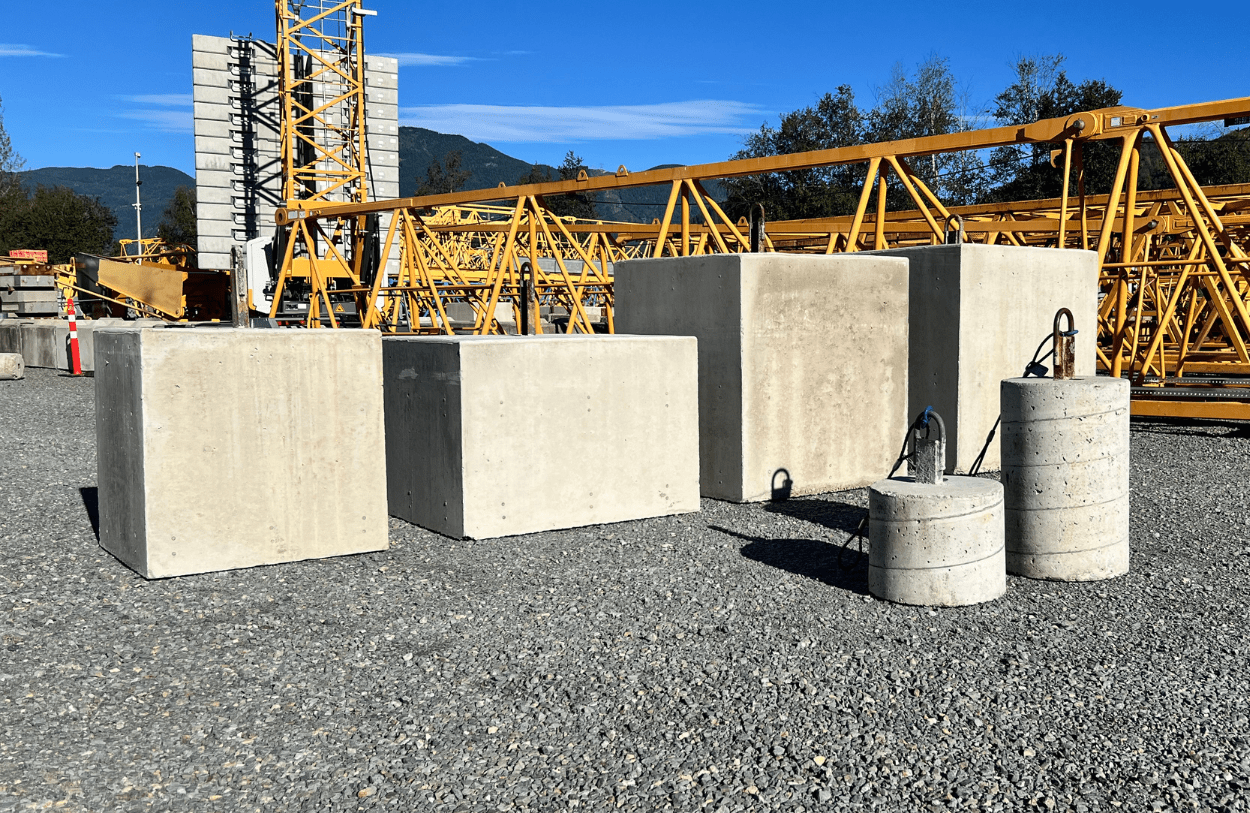

Safety on Construction Sites and Crane Operations

Strong wind can interfere with lifting equipment or create serious risks for workers at height. Gusts may cause cranes to shift, loads to sway, or scaffolding to become unstable. Anemometers placed on cranes or rooftops provide real-time readings. Crews use this data to pause work when wind becomes unsafe, helping to prevent injuries or equipment damage.

Weather Forecasting and Storm Tracking

Wind plays a major role in weather systems. Meteorologists use wind data to track fronts, pressure shifts, and storm development. A change in wind speed or direction may signal incoming rain, colder temperatures, or stronger weather events. Forecast accuracy depends on consistent data, and wind readings help build models people can rely on. This information supports decisions in farming, aviation, and daily life.

Designing Structures That Can Handle the Wind

Architects and engineers use wind measurements when designing buildings, towers, and bridges. Wind applies force to every surface it touches. Knowing how wind behaves in a specific location helps guide design choices. It shapes everything from material selection to window placement. With the right data, structures can stay secure while also allowing proper ventilation and airflow.

Improving Wind Energy Efficiency

Wind turbines depend on steady airflow to perform well. Anemometers help locate the best positions for turbines and allow teams to monitor daily output. Even small changes in wind patterns affect how much energy a turbine can produce. Reliable data helps make the system more efficient and supports long-term planning for energy needs.

How Anemometers Work

An anemometer works by sensing air movement and converting it into wind speed or direction data. Each type uses a different method, but the purpose is the same: turning invisible wind into useful, measurable information.

Cup Anemometers

A cup anemometer has several small cups attached to arms that spin around a central point. Wind pushes the cups, and the faster they spin, the stronger the wind. A sensor counts the number of rotations to calculate wind speed. These are often used on weather stations, towers, and rooftops.

Vane Anemometers

This type has a fan blade that spins when wind flows through it. The speed of rotation shows how fast the wind is moving. Many vane anemometers also include a tail that points into the wind, which helps show direction. These devices are common on portable meters and used in outdoor work.

Hot-Wire Anemometers

A hot-wire anemometer uses a thin wire heated by electricity. As wind passes over the wire, it cools it down. The faster the cooling, the faster the wind. The device measures this temperature change and uses it to calculate wind speed. These are mostly used indoors in labs, ductwork testing, or air system setups.

Ultrasonic Anemometers

This type sends sound waves between two or more sensors. Wind changes the time it takes for the sound to travel. Small time shifts in the signal help calculate both speed and direction. These anemometers have no moving parts and are often used in places where maintenance needs to stay low.

Pitot Tube Anemometers

This design measures wind speed using pressure. Wind enters a small opening, creating a pressure difference. The device compares this against static pressure to calculate how fast the air is moving. Pitot tubes are often used in aircraft and wind tunnels.

Industry Applications

Anemometers have several uses. They have become key tools across many industries, but their impact on modern weather forecasting stands out. They helped shift forecasting from rough patterns to science-based predictions by turning wind into measurable data. Today, wind data supports better planning in construction, aviation, agriculture, marine operations, and renewable energy systems.

Construction and Crane Operations

Work at height involves constant attention to wind. On construction sites, cranes lift heavy materials that can become unstable in strong gusts. A sudden shift in wind can move a load unexpectedly or cause a crane to sway. Anemometers provide real-time wind data that helps operators decide when to lift and when to stop. Having this information available on site supports safer decisions and helps crews avoid unnecessary risks during lifting operations.

Meteorology and Forecasting

Weather experts use wind readings to track moving air masses and predict how storms or cold fronts will behave. Anemometers help meteorologists measure both the speed and direction of wind at ground level and at higher altitudes. These measurements feed into forecasting models that people rely on for planning daily activities. Whether preparing for a rainfall or monitoring a developing storm, wind data plays a central role in getting those predictions right.

Aviation Safety and Flight Management

Airports depend on accurate wind information to keep flights on schedule and safe. Runway direction, aircraft weight, and current wind conditions all influence how pilots take off or land. Anemometers near runways measure surface wind and help air traffic controllers guide aircraft during key phases of flight. In the air, wind affects route choices and fuel use. Good data helps pilots adjust and respond with confidence.

Wind Energy Monitoring

Wind turbines need a steady flow of air to work well. Anemometers are placed at turbine height to track wind speed and direction throughout the day. That information helps adjust blade angles and maintain alignment. When turbines face the wind properly, they produce more power and wear down less quickly. Wind data also helps choose the best locations for new turbines and track long-term energy output.

Marine and Offshore Use

Wind affects navigation, fuel use, and crew safety in open waters. Ships and offshore platforms use anemometers to monitor wind changes during travel or heavy lifting. Real-time data supports better planning and helps avoid sudden shifts that could lead to damage or delay.

Choosing the Right Anemometer

Choosing an anemometer starts with understanding what the job demands. Every model works to measure wind, but some are better suited for fixed locations, while others serve best in the field. The right choice depends on how and where the tool will be used.

Accuracy and Reliability

Accuracy matters when decisions rely on data. In high-risk environments like crane operations or aviation, even small errors in wind speed can create big problems. Devices that help steady and consistent readings teams work with better judgment and fewer interruptions.

Durability and Weather Resistance

Anemometers placed outdoors face sun, rain, and dust every day. Sturdy anemometer parts keep the device working through all seasons. Weatherproof housing, corrosion-resistant parts, and a sealed design can make the difference between a short-term fix and a long-term solution.

Mounting Type and Use Case

Some anemometers are made to stay in one place. Others need to move from site to site. Fixed units work well on rooftops, towers, and cranes. Handheld versions are better for mobile teams, inspections, or temporary setups. The choice depends on how often the tool moves and who uses it.

Useful Features That Support the Job

Extra functions can make daily tasks easier. Real-time alerts can warn a team about sudden wind changes. Digital screens make readings easier to read on the go. Logging features let users track patterns and review data over time.

Maintenance & Calibration

Regular maintenance keeps an anemometer accurate and dependable. Dust, salt, or moisture buildup can affect how well moving parts spin or how sensors respond. Cleaning the unit gently with a soft cloth and checking for any signs of wear can help prevent unexpected failures. This is especially important in outdoor, marine, or construction environments where conditions change fast.

Calibration Should Match Use and Environment

The accuracy of any wind measurement tool depends on regular calibration. Devices used every day, exposed to harsh weather, or installed in high-vibration areas should be calibrated more often than those in controlled environments. While many manufacturers suggest once a year, some sites benefit from calibration every six months. A regular schedule reduces drift and keeps readings within acceptable limits.

Knowing When to Replace or Upgrade

Keeping track of part wear can prevent unexpected downtime. Spinning parts may begin to lag, sensors may lose precision, or displays may stop responding clearly. Instead of pushing through unreliable performance, it often makes sense to replace key parts or invest in a newer model. Upgrading can also introduce features that improve daily use or reduce maintenance time.

Future Trends in Wind Monitoring

Wind monitoring is moving beyond basic readings. New anemometers now include smart sensors that connect to wider systems using IoT technology. These tools can send data instantly to phones, tablets, or control rooms.

Predictive Safety and Early Warnings

Instead of waiting for dangerous gusts, some systems now predict risk based on patterns. Alerts can warn crane operators or site managers before wind conditions reach unsafe levels.

Fully Connected Worksites

Modern anemometers are being linked with broader site systems like BIM platforms and fleet management tools. This makes wind data part of the bigger picture in planning and safety.

Conclusion

At Bigfoot Crane Company, we provide trusted anemometers and wind monitoring systems that support safer crane operations. Our tools give your crew the real-time data they need to make smart, informed decisions on-site. We understand how fast wind conditions can change, and we’re here to help you stay ready every day. Contact us to get the right wind solution for your job.