In the construction and heavy-lifting industries, safety and efficiency is of the utmost importance. To achieve both, you need to know everything about under hook accessories (UHA) which are attachments used in crane operations. This article explores the importance, types, and best practices for utilizing these essential tools. It aims to provide a better approach that ensures efficiency and safety of lifting operations, how each part is supposed to work, and what should be inspected.

What Are Under Hook Accessories?

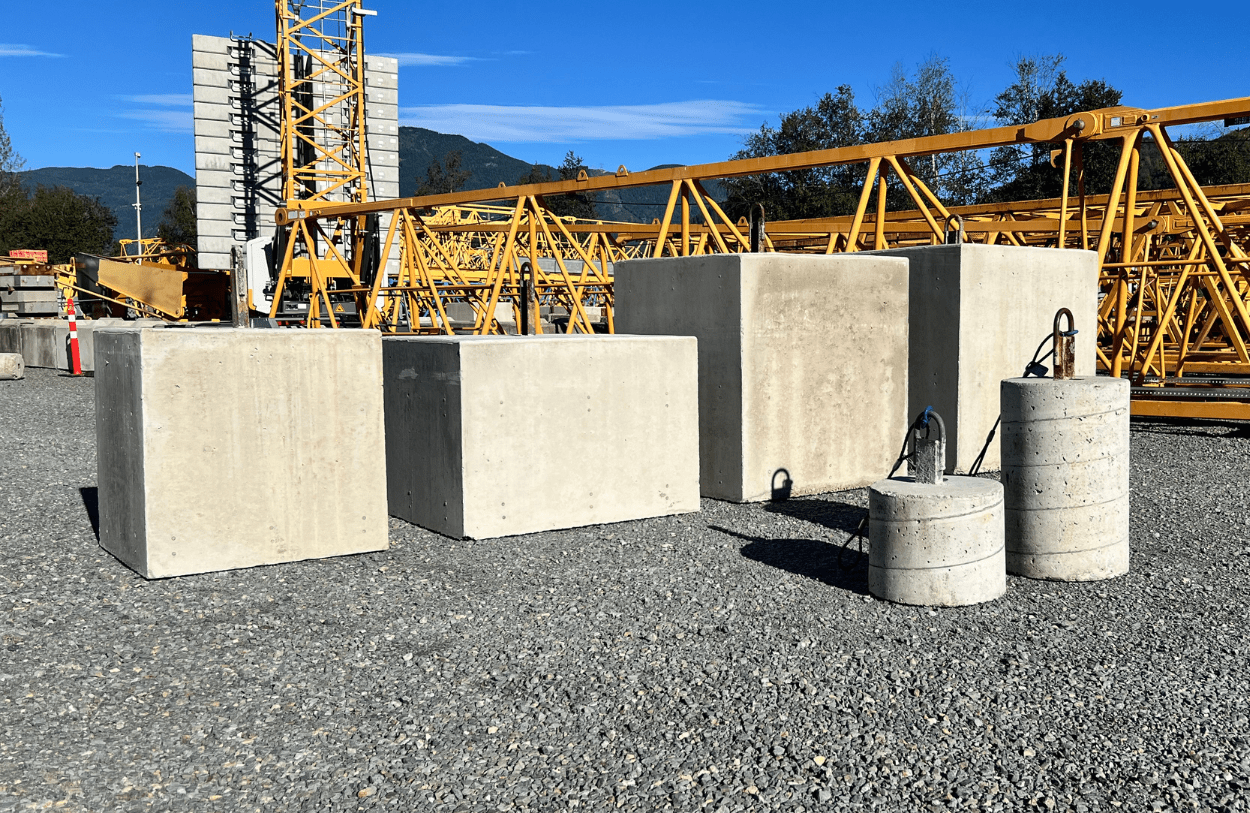

Under hook accessories, also known as below-the-hook lifting devices, are specialized tools and equipment attached to the crane’s hook to facilitate the lifting and handling of various materials. The right tool ensures material handling is done safely and efficiently. They play a crucial role in preventing accidents and maximizing efficiency.

These accessories are used across various industries, including construction, manufacturing, and logistics. They facilitate material handling such as steel beams, concrete slabs, and large materials components [and people]. Their versatility makes them indispensable tools in any operation requiring heavy lifting.

Types of Under Hook Accessories

Understanding the different types of lifting accessories for cranes is important in order to choose the right piece of equipment. Each categories has a very specific job and works best with certain types of loads.

Overview of common underhook accessories:

Lifting Beams

Lifting beams are horizontally placed structures that allow a load to be evenly distributed across multiple locations. These are ideal for raising long and heavy objects that require support at various points. They come in various configurations, such as fixed, adjustable, and telescopic, catering to different lifting requirements.

Fixed Lifting Beams

A fixed lifting beam is a non-adjustable structure with a predetermined length They are used when the distance between lifting points is consistent. These beams are sturdy and reliable, providing a stable lift for heavy loads.

Adjustable Lifting Beams

Adjustable lifting beams offer flexibility providing a range of applications to handle loads in different lengths. The adjustable sizing of the fork arms enables them to be used in different lifting points, making them a useful tool for environments where load dimensions are not constant and change frequently.

Telescopic Lifting Beams

Telescopic lifting beams can extend and retract to accommodate different load sizes. This function makes them adaptable to use and can adjust based on specific lifting requirements especially where space constraints are a concern.

Spreader Bars

Spreader bars function similarly to lifting beams but are designed to spread the load over a wider area. This keeps the load stable and balanced, making them ideal for lifting large cumbersome objects. They are especially useful in situations where the load’s center of gravity is not centralized.

Single-Point Spreader Bars

Single-point spreader bars are designed for loads with a single lifting point. They distribute the load evenly, ensuring stability during lifting. These bars are simple to use and are suitable for straightforward lifting tasks.

Multi-Point Spreader Bars

Multi-point spreader bars have multiple lifting points, providing enhanced stability for larger and more complex loads. These bars are used in situations where the load needs to be balanced across several points to prevent tipping or shifting.

Plate Clamps

Plate clamps are used for lifting and handling heavy, flat materials like steel plates. They come in various designs, including vertical, horizontal, and universal clamps. These clamps provide a secure grip on the material, ensuring it is lifted safely without slipping.

Vertical Plate Clamps

Vertical plate clamps are designed to lift plates in a vertical orientation. They provide a strong grip and are used in applications where the plates need to be lifted and transported upright.

Horizontal Plate Clamps

Horizontal plate clamps lift plates in a horizontal position. They are used when plates need to be lifted flat and provide a secure grip, preventing the plates from slipping during lifting operations.

Universal Plate Clamps

Universal plate clamps are versatile tools that can lift plates both vertically and horizontally. They offer flexibility and are ideal for environments where lifting requirements frequently change.

Coil Lifters

Coil lifters are specifically designed for handling coiled materials such as steel or aluminum coils. These devices can lift coils vertically or horizontally, providing flexibility in handling different types of coiled materials. Their design ensures the coils are lifted securely, reducing the risk of damage or accidents.

Vertical Coil Lifters

Vertical coil lifters lift coils in a vertical orientation, providing a secure grip around the coil’s circumference. These lifters are ideal for handling coils that need to be stored or transported upright.

Horizontal Coil Lifters

Horizontal coil lifters lift coils in a horizontal position, ensuring they remain stable during lifting. These lifters are used when coils need to be laid flat for storage or transport.

Pallet Lifters

Pallet lifters are used for handling palletized loads and are commonly referred to as pallet fork crane attachments in construction, warehousing, and industrial lifting applications. They come in various configurations, including fork-style and clamp-style lifters. These devices provide a secure grip on the pallet, ensuring it is lifted and transported safely.

Fork-Style Pallet Lifters

Fork-style pallet lifters are similar to forklift forks and slide under the pallet to lift it. They are easy to use and provide a stable lift for palletized loads.

Clamp-Style Pallet Lifters

Clamp-style pallet lifters grip the sides of the pallet, providing a secure hold during lifting. These lifters are used when the pallet’s structure or load requires additional stability.

Drum Lifters

Drum lifters are designed for lifting and handling cylindrical containers such as drums and barrels. They come in different designs, including clamp-style and fork-style lifters. These devices provide a secure grip on the drum, ensuring it is lifted and transported safely.

Clamp-Style Drum Lifters

Clamp-style drum lifters grip the top rim of the drum, providing a secure hold during lifting. They are used for lifting drums in a vertical orientation.

Fork-Style Drum Lifters

Fork-style drum lifters slide under the drum to lift it, providing a stable lift for horizontal or vertical transport. These lifters are versatile and easy to use.

C-Hooks

C-hooks are used for lifting and handling loads with a central opening, such as coils or rolls. These devices have a C-shaped design that allows them to hook into the load’s central opening, providing a secure grip for lifting.

Fixed C-Hooks

Fixed C-hooks are rigid and designed for loads with consistent central openings. They provide a stable and secure lift for heavy items.

Adjustable C-Hooks

Adjustable C-hooks can be modified to fit different load sizes, offering flexibility in handling various materials. They are ideal for environments with diverse lifting requirements.

Vacuum Lifters

Vacuum lifters use suction to grip and lift materials. They are ideal for handling non-porous materials like glass, metal, and plastic sheets. These devices provide a secure grip without damaging the material, making them perfect for delicate or fragile items.

Single-Cup Vacuum Lifters

Single-cup vacuum lifters use one suction cup to grip the material. They are suitable for smaller items or materials with a uniform surface.

Multi-Cup Vacuum Lifters

Multi-cup vacuum lifters use multiple suction cups to distribute the lifting force evenly. They are used for larger or heavier items, providing enhanced stability during lifting.

Importance of Proper Inspection and Maintenance

Proper inspection and regular maintenance of under hook accessories are crucial for ensuring their safe and efficient operation. Regular inspections help identify any signs of wear, damage, or other issues that could compromise the safety of the lifting operation. Maintenance practices should include cleaning, lubrication, and repairs as needed to keep the devices in optimal condition.

Inspection Requirements

Inspection requirements for under hook accessories can be found in various industry standards and regulations. These guidelines outline the frequency and scope of inspections, ensuring that the devices are safe to use. For example, the American Society of Mechanical Engineers (ASME) provides detailed guidelines for the inspection and maintenance of lifting devices.

Daily inspections involve checking the accessory for visible signs of damage, wear, or other issues. This includes looking for cracks, deformations, or loose parts. Daily checks ensure that the accessory is safe to use before each operation. On the other hand, monthly inspections are more thorough and involve a detailed examination of the accessory. This includes checking all moving parts, connections, and safety measures Any issues identified during these inspections should be addressed promptly to ensure the accessory’s safety and functionality.

Annual inspections are comprehensive evaluations conducted by qualified professionals. These inspections include detailed assessments of the accessory’s structural integrity, mechanical components, and safety features. Annual inspections help ensure that the accessory remains in good working condition and ensure the safety industry standards.

Device Maintenance Best Practices

Adhering to best practices for maintenance is essential for prolonging the lifespan of under hook accessories and ensuring their safe operation. This includes regular cleaning to remove dirt and debris, lubrication of moving parts to prevent wear, and prompt repairs of any damage. Proper storage of these devices is also crucial to prevent damage when they are not in use.

Cleaning

Regular cleaning helps remove dirt, grease, and other contaminants that can affect the accessory’s performance. Use appropriate cleaning agents and methods to avoid damaging the material or components.

Lubrication

Lubrication of moving parts reduces friction and wear, ensuring smooth operation. Use suitable lubricants for the specific accessory and follow manufacturer recommendations for application frequency and methods.

Repairs

Prompt repairs of any identified issues are crucial for maintaining the accessory’s safety and functionality. Use qualified professionals for repairs and ensure that all components meet industry standards.

Storage

Proper storage of under hook accessories helps prevent damage when they are not in use. Store accessories in a clean, dry environment, away from corrosive substances and extreme temperatures. Use appropriate storage racks or containers to protect them from physical damage.

Enhancing Safety with Under Hook Accessories

Safety is a top priority in any lifting operation, and under hook accessories play a vital role as crane attachments for material handling by improving stability, control, and overall jobsite safety. These devices help prevent accidents and injuries by providing additional support and stability. Here are some ways under hook accessories contribute to safer lifting solutions:

Load Stability

Under hook accessories help distribute the load evenly, ensuring it remains stable during lifting. This reduces the risk of the load shifting or falling, which could lead to accidents or damage.

Balancing the Load

Balancing the load is crucial for safe lifting operations. Under hook accessories like lifting beams and spreading bars / spreader bars help balance the load by distributing the weight evenly across multiple points. This ensures that the load remains stable and prevents tipping or shifting.

Securing the Load

Securing the load involves ensuring that the material is firmly attached to the lifting accessory. Accessories like plate clamps and coil lifting provide a secure grip on the material, preventing it from slipping or falling during lifting. Properly securing the load reduces the risk of accidents and damage.

Secure Grip

Under hook accessories provide a secure grip on the load, ensuring it is lifted safely without slipping. This is especially important when handling heavy loads or awkwardly shaped items.

These accessories use various gripping mechanisms to secure the load. For example, vacuum lifters use suction to grip the material, while plate clamps use mechanical clamping forces. Understanding the gripping mechanism of each accessory helps ensure the load is lifted securely.

Many under hook accessories come with safety features designed to enhance the grip on the load. These features include locking mechanisms, anti-slip surfaces, and load indicators. Utilizing accessories with advanced safety features helps ensure a secure grip on the load and prevents accidents.

Reduced Manual Handling

Using under hook accessories reduces the need for manual handling of heavy loads, minimizing the risk of injuries. This also helps improve efficiency, as loads can be lifted and transported more quickly and easily. They provide ergonomic benefits by reducing the physical strain on workers. Mechanizing the lifting process with these accessories minimizing the need for manual lifting, bending, and carrying. This helps reduce the risk of musculoskeletal injuries and improves worker safety.

Reducing manual handling not only enhances stability but also improves efficiency. Under hook accessories like adjustable lifting beams and telescopic spreader bars reducing setup time by allowing quick adjustments to fit difficult load sizes. This flexibility minimizing the time required for setup and reconfiguration, enhancing operational efficiency.

Compliance with Safety Standards

Under hook accessories are designed to meet various safety standards and regulations, ensuring they are safe to use. This helps companies comply with legal requirements and maintain a safe working environment.

Industry Standards

Industry standards such as those provided by ASME and OSHA outline the safety requirements for under hook accessories. These standards cover aspects such as design, manufacturing, testing, and inspection. Using accessories that meet industry standards helps ensure their safety and reliability.

Legal Compliance

Complying with safety standards and regulations is a legal requirements in many industries. Using under hook accessories that meet these standards helps companies avoid legal issues and ensures a safe work environment. Regular inspections and maintenance are also necessary to maintain compliance with safety protocols.

Improving Efficiency with Under Hook Accessories

In addition to enhancing safety, under hook accessories also improve the efficiency of lifting operations. These devices enable cranes to lift heavier loads more quickly and easily by providing additional support and stability. Here are some ways under hook accessories contribute to more efficient lifting operations:

Faster Lifting

Under hook accessories enable cranes to lift loads more quickly, reducing the time needed for lifting operations. This helps improve productivity and reduces downtime. They streamline lifting operations by providing precise and efficient handling of materials. For example, vacuum lifters allow for quick attachment and release of materials, speeding up the lifting process. Streamlined operations contribute to faster lifting and improved productivity.

Accessories like adjustable lifting beams and telescopic spreader bars reduce setup time by allowing quick adjustments to fit different load sizes. This flexibility minimizes the time required for setup and reconfiguration, enhancing operational efficiency.

Increased Load Capacity

Under hook accessories enhance the capabilities of cranes by allowing them to lift loads that would otherwise be too heavy. This increased load capacity enables companies to take on larger projects and handle more demanding lifting requirements. They maximize the utilization of cranes by increasing the load capacity. This means that cranes can be used for a wider range of tasks, reducing the need for additional equipment and optimizing resource allocation.

Versatility

Under hook accessories come in various designs and configurations, providing flexibility in handling different types of loads. This versatility helps companies adapt to different lifting requirements, improving efficiency.

Adapting to Different Loads

Versatile under hook accessories can handle a wider range of loads, from flat plates to cylindrical drums. This adaptability allows companies to use a single accessory for multiple tasks, reducing the need for specialized equipment and simplifying inventory management.

Some under hook accessories offer customizable solutions to meet specific lifting requirements. For example, adjustable lifting beams and telescopic spreader bars can be tailored to fit different load sizes and configurations. Customizability solutions enhance the versatility of under hook accessories and improved operational efficiency.

Reduced Downtime

Accidents and equipment failures can cause significant downtime and disrupt operations. Under hook accessories enhance safety and reliability, hence minimize the risk of accidents and reduce downtime. This contributes to more consistent and efficient lifting operations.

Properly maintained under hook accessories enhance the reliability of lifting equipment. Regular inspections and maintenance ensure that accessories remain in good working condition, preventing unexpected failures and reducing downtime.

Key Considerations for Using Under Hook Accessories

When using under hook accessories, it is important to consider various factors to ensure their safe and efficient operation. Here are some key considerations to keep in mind:

Load Characteristics

Understanding the characteristics of the load is crucial for selecting the right under hook accessory. This includes the load’s weight, size, shape, and center of gravity. Choosing the right accessory for the load helps ensure it is lifted safely and efficiently.

Accurately assessing the load’s weight is essential for selecting the appropriate under hook accessories. Using an accessory with insufficient load capacity can compromise safety and lead to accidents. Ensuring that the accessory’s load capacity matches or exceeds the weight of the load.

The shape of the load affects the type of under hook accessories needed. For example, flat plates require plate clamps, while cylindrical drums need drum lifters. Evaluating the load’s shape helps determine the most suitable accessory for safe and efficient lifting.

Compatibility with Crane

Under hook accessories must be compatible with the crane being used. This includes ensuring the accessory can be securely attached to the crane’s hook and that it can handle the crane’s load capacity. Compatibility is crucial for safe and efficient lifting operations.

Ensuring that the under hook accessories can be securely attached to the crane’s hook is essential for safe lifting. Check that the attachment mechanism is compatible with the crane’s hook size and configuration. A secure attachment prevents the accessory from detaching during lifting operations.

The load capacity of the under hook accessories must match or exceed the crane’s load capacity. Using an accessory with insufficient load capacity can compromise safety and lead to equipment failure. Ensuring that the accessory is rated for the maximum load weight.

Inspection and Maintenance

Conducting regular inspections of under hook accessories to identify any signs of wear, damage, or other issues. Following industry standards and manufacturer guidelines for inspection frequency and procedures. Regular inspections help prioritize safety and reliability of the accessories.

Implementing maintenance practices such as cleaning, lubrication, and repairs to keep under hook accessories in good working condition. Following manufacturer recommendations for maintenance procedures and use qualified professionals for repairs. Proper maintenance extends the lifespan of the accessories and ensures safe operation.

Training and Certification

Provide comprehensive training for crane operators on the safe and effective use of under hook accessories. This includes training on selecting the right accessory, attaching and securing the accessory, and operating the crane safely. Proper training helps prevent accidents and ensures efficient lifting operations.

Implement certification programs to ensure that operators and personnel have the necessary knowledge and skills to use under hook accessories safely. Certification programs provide standardized training and assessment, ensuring that personnel meet industry safety standards.

Conclusion

Under hook accessories are essential tools for ensuring safety and efficiency of overhead crane lifting operations. By providing additional support and stability, these devices help prevent accidents and injuries, improve productivity, and reduce downtime. Understanding the types, importance of proper inspection and maintenance, and key considerations for using under hook accessories is crucial for ensuring their safe and efficient operation.

For more information on under hook accessories and how they can enhance your lifting operations, contact us today to learn or visit our website at www.bigfootcrane.com. Our comprehensive range of under hook accessories is designed to meet various lifting needs, ensuring safe and efficient lifting operations.