The towering presence of cranes on the urban skyline has become an emblem of progress, efficiency, and sheer engineering skill. Yet, not all cranes are created equal, and the nuances in design and function can drastically affect how they serve the projects that reach for the heavens. From the towering spires seen in cityscapes to the intricate machinations within industrial sites, understanding the range of tower crane types is crucial for construction professionals and project managers alike.

This blog post will dissect the intricacies of various types of tower cranes, their applications, and what makes each one the ideal for a particular construction project. We aim to give a comprehensive overview, not only for professionals familiar with construction equipment, but also for those who wish to deepen their knowledge in the ever-upward industry of construction technology.

Top Slewing Tower Cranes: The Skyline Champions

Top-slewing cranes—more widely known as tower cranes—are defined by a rotating slewing unit mounted on top of a tall mast, allowing the jib to swing full-circle around the structure. These cranes are essential on high-rise and large-scale construction projects, offering unmatched reach and lifting capability at significant heights. Variants include flat-top cranes, high-top cranes, and those with a luffing jib configuration, each suited for different site conditions and lifting needs.

Hammerhead Tower Cranes: Scaling New Heights

Often seen dominating city skylines, hammerhead cranes—sometimes called A-frame tower cranes and High-top tower cranes—are a type of top-slewing crane recognizable by the signature triangular metalwork above their mast. The High-Top Tower Crane stands out for its higher capacity to lift heavier loads and accommodate a longer jib. This makes it the preferred choice for mid to large-sized construction projects where heavier materials and a longer reach are essential.

These cranes are especially favored in urban environments thanks to their balance of lifting power and efficient use of space. While some people refer to these as “topless” or flat-top cranes, there’s a key distinction: A-frame cranes feature a rigid steel framework connecting the jib and counter-jib in the shape of an “A,” whereas flat-top cranes eliminate that upper bracing for easier assembly and disassembly in tight or obstructed areas.

Flat-Top Tower Cranes: The Urbanite’s Pick

The Flat-Top Tower Crane is custom-built for urban work. The absence of a cat-head and counter-jib allows for a small footprint, vital in the confined city space. Easy to erect and dismantle, Flat-Tops are designed for quick turnaround projects that require regular repositioning.

Luffing Tower Cranes: The High-Density Lifters

Where space becomes premium and the need to maintain free air space over a busy site is paramount, the Luffing Tower Cranes shine. Their jib is designed to raise and lower, offering the advantage of high-rise construction in confined areas without the risk of interference.

Heavy Load Tower Cranes: Titans of Industry

For the colossal tasks in industrial sectors like mining, ports, or oil and gas, the Heavy Load Tower Cranes are the unsung heroes. These massive machines are purpose-built to handle weighty materials with precision, safety, and robust lifting mechanisms that tame the toughest of terrains.

Derrick Cranes: The Sky Descenders

Once construction completes, the opposite of an Erecting Crane becomes vital — the dismantling crane, often referred to as a Derrick Crane. This tower crane type is engineered specifically for the controlled disassembly of skyscrapers and other high-rise structures, ensuring that deconstruction is as safe and meticulous as the construction itself.

Fast Erecting Tower Cranes: The Mach Speed Performers

A subclass of tower cranes, Fast-Erecting Cranes, lives up to their name by offering unprecedented speeds in the setup and disassembly process. Their quick mobilization and demobilization make them well-suited for construction projects requiring frequent relocation within a job site or rapid deployment across multiple sites.

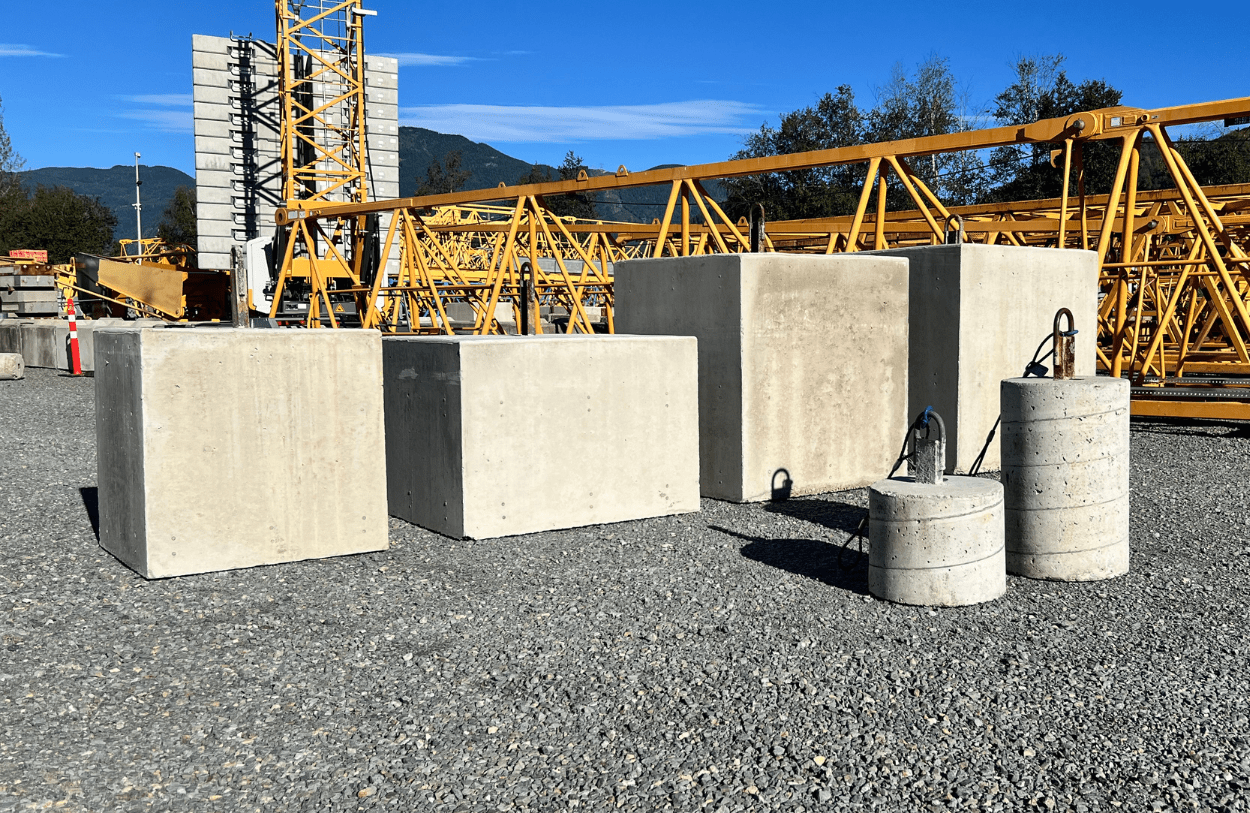

Fixed Base with No Fixed Wheels: Stability and Versatility

With a tower constructed from lattice bracing and no wheels to move, these cranes are a symbol of stability and strength. They are frequently employed in hybrid designs, serving as light-duty auxiliary cranes or on specialized sites.

Mobile Fast Erecting: The Agile Urban Sculptors

Equipped with wheels and outriggers that serve as the crane’s support system, the Mobile Fast-Erecting Tower Cranes are the agile choice for urban development projects that require rapid repositioning. Their adaptability to the quick rhythm of city construction projects cannot be overstated.

Crawler: Tracking Progress in Heavy-duty Style

Designed with a similar concept to the Mobile Fast-Erecting, the Crawler Tower Cranes take that agility to heavy-duty extremes with a tracked undercarriage that can conquer almost any terrain. These cranes are typically used in the toughest construction environments such as dam works or high-altitude projects.

The Future of Construction Cranes: Navigating Innovation and Integration

In a tech-driven world, tower cranes are not immune to innovation. The integration of digital technologies from sensors to advanced automation is enhancing safety, efficiency, and environmental sustainability. With new materials and engineering concepts constantly being developed, the next generation of tower cranes promises even greater flexibility and precision in construction operations.

Conclusion: Choosing the Right Crane for the Task at Hand

Dissecting the different types of tower cranes reveals a complex world of engineering tailored to the specific needs of construction projects. By understanding the strengths and limitations of each crane type, project managers and construction professionals can select the perfect machinery to maneuver through the intricacies of their unique build. As the construction industry continues to grow, so too will the demand for technology that reaches new heights, and tower cranes are — quite literally — at the peak of this trend.

In this age of vertical progression, the specialized nature of tower cranes underscores the importance of informed decision-making in construction equipment procurement. It’s not just about lifting; it’s about doing so with precision, safety, and the kind of finesse that only comes from understanding the different types of tower cranes and matching them to the correct job site. The skyline is the limit, and these tower cranes are the architects of our construction future.