Tower crane safety lives in daily discipline rather than checklists, because steady habits guide decision when pressure rises on active sites. Shared responsibility across operators, supervisors, riggers, and project managers shapes the tone of every lift and every pause. Small habits such as clear calls, calm movements, and honest stop decisions build long term outcomes that protect people, schedules, and equipment. This article offers practical guidance grounded in real site conditions, drawing on what crews see and manage each day. Bigfoot works close to field realities through planning, coordination, and support, which informs the perspective shared here without turning the message into promotion.

Strong Planning Before the Crane Arrives on Site

Strong planning before a crane arrives on site sets the tone for safe work and steady progress, because thoughtful preparation shapes every decision that follows. Teams gain clarity when lift plans are discussed early, rather than rushed under schedule pressure. Careful review of site conditions, ground bearing pressure, access routes, and swing radius helps everyone understand what the job truly demands before equipment moves.

Clear confirmation that crane selection matches project requirements protects both productivity and safety. Projects benefit when capacity, reach, and configuration align with real lifting needs instead of hopeful assumptions. Early coordination between the contractor, crane provider, and engineering teams also builds shared understanding, which keeps communication open and expectations realistic.

Good planning reduces last minute changes that often lead to stress, confusion, and avoidable risk. Crews feel more confident when plans feel practical and grounded in the actual site environment. Strong preparation also supports smoother erection, cleaner flowrworks, and better use of time across the entire project lifecycle.

Safe Erection and Dismantle Practices

Safe erection and dismantle practices shape the safety culture of a project because the first days on site influence how teams behave throughout the work. Qualified crews bring calm control to assembly and dismantle, which reduces confusion and supports consistent decision making when conditions change. Clear use of documented procedures and manufacturer guidance gives every team member a shared reference point, rather than relying on memory or habit.

Open communication between the supervisor, lead erectors, and rigging crew, keeps each step coordinated and helps issues get addressed before they grow into hazards. Defined controlled zones and exclusion areas also protect everyone on site, since movement stays predictable and access remains managed during high risk activities. Strong attention to these details creates a professional rhythm that crews can follow as the project moves forward. Crane erection safety does not feel like a separate task when handled well, it becomes part of the daily mindset that supports steady progress and safer outcomes.

Operator Habits That Influence Site Safety Every Day

Operator habits shape site safety in ways that everyone can feel, since consistent behavior in the cab sets the tone for the entire lift environment. Pre shift inspections become a daily routine that builds confidents in the machine and gives operators a clear picture of what needs attention before work begins. Smooth, controlled movements protect the load, protect the structure, and help ground crews stay calm and focused during busy periods.

Situational awareness also plays a strong role, especially around blind lifts and congested areas where communication must stay sharp at all times. Respecting load charts and resisting pressure to rush lifts shows professionalism that others quickly recognize and follow. Crews tend to mirror the discipline they see in the cab, which improves teamwork and trust across the site. Strong operator habits rarely draw attention when everything runs well, yet those quiet choices each day often make the difference between predictable progress and unnecessary risk.

Communication as a Core Safety Tool

Clear communication shapes how safely a lift unfolds, since every movement depends on shared understanding between the operator, the signal person, and the ground crew. Radio calls that stay simple and consistent reduce guesswork and help everyone stay aligned, especially when visibility drops or the site feels busy and unpredictable. Trained signal persons bring structure and calm to that exchange, which gives operators confidence that directions are accurate and timely.

Miscommunication often sits behind incidents that never needed to happen, usually caused by rushed wording, mixed messages, or assumptions about what others can see. Industry standard hand signals offer a dependable backup when radios struggle, while practiced procedures give teams something familiar to fall back on during complex lifts. Consistent communication also builds trust across the lift team because everyone feels heard and respected. That trust encourages people to speak up early, which supports safer decisions and steadier progress throughout the day.

Managing Wind, Weather, and Environmental Conditions

Changing weather conditions place real pressure on tower crane operations, since decisions must balance production goals with the duty to keep every person safe on site. Wind speed influences load stability and crane response, which means operators and supervisors need agreed upon limits that guide when lifts pause. Rain and ice create slippery surfaces and unpredictable loads, adding risk during rigging and travel. Visibility drops during fog or heavy weather, which challenges communication and raises the chance of missed cues.

Site teams rely on consistent weather monitoring practices, including local forecasts, on site wind readings, and shared updates across the crew. Clear thresholds give operators confidence to stop work when conditions shift. Strong leadership encourages pauses without blame, so people feel supported rather than pressured to push through. Open conversations during toolbox talks help normalize weather based decisions. Practical discipline during changing conditions protects equipment, supports steady schedules, and builds a culture where safety choices feel respected.

Load Management and Rigging Discipline

Load management and rigging discipline shape the safety of every lift because each choice made at ground level carries through the entire operation. Proper rigging selection starts with understanding the task, the hardware available, and the condition of slings, shackles, and lifting points. Verified load weights give operators the confidence to plan movements calmly instead of reacting mid lift. Center of gravity awareness helps prevent unexpected shifts that can place stress on the crane or swing the load into people and structures.

Side loading and shock loading create avoidable strain on components, which is why steady control and thoughtful rigging matter on even routine picks. Teams that slow down during setup often work faster overall because lifts flow smoothly and corrections stay minimal. Riggers who speak up, supervisors who listen, and operators who trust the process build a rhythm that protects everyone involved. Disciplined rigging supports safer sites, stronger equipment performance, and a culture where care feels natural rather than forced.

Documentation and Compliance Support Safer Outcomes

Strong documentation habits support safer outcomes because clear records show what has been checked, confirmed, and approved on site. Daily logs, inspection reports, and certification records give crews confidence that equipment and processes meet agreed standards. People working around the crane feel safer when paperwork reflects real actions rather than assumptions. This kind of record keeping protects operators, supervisors, contractors, and owners when questions arise, since decisions can be traced and understood.

Proper records also support accountability in a practical way. Names, dates, and findings make responsibility visible, which encourages careful work across every role. Availability of documentation on site matters just as accuracy, because teams need access during planning, audits, and unexpected events. A culture that values clear records often shows stronger teamwork and communication. Crews take greater pride in their work when professionalism shows in both actions and paperwork. Over time, disciplined documentation habits build trust across the site and support safer daily operations.

How Bigfoot Supports Safer Crane Operations

Bigfoot Crane plays an important role in helping construction teams maintain safe crane operations through structured processes and careful coordination. Our approach goes beyond equipment provision, focusing on supporting crews before, during, and after each lift. Effective planning and organized logistics reduce rushed decisions and minimize hazards on site.

Storage and Transport Support

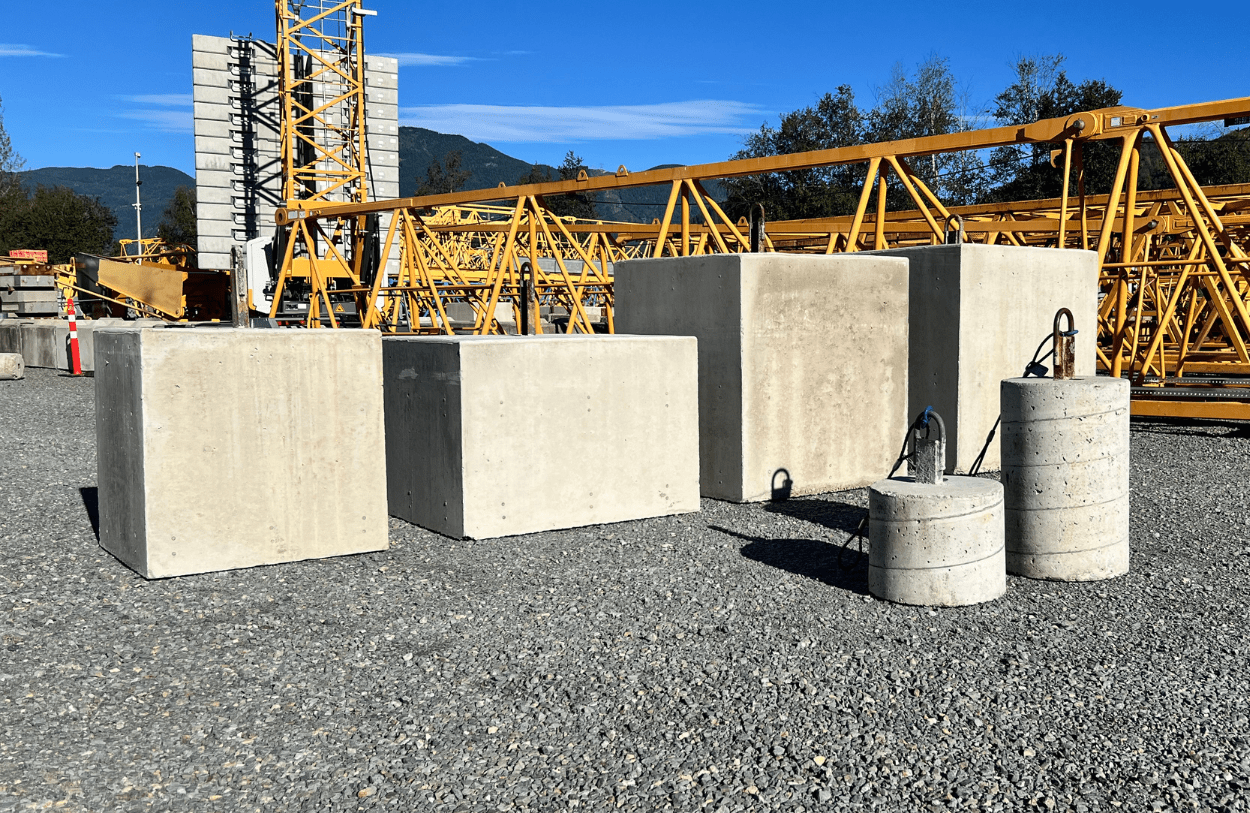

Proper storage and careful transport ensure cranes arrive ready for operation. Bigfoot’s organized facilities and coordinated mobilization reduce handling risks and allow crews to focus on safe setup rather than troubleshooting equipment issues.

Erection and Operational Alignment

During assembly and dismantle, Bigfoot works with teams to align crane setup with project needs, ground conditions, and manufacturer guidance. This coordination helps maintain consistent standards and supports safe practices across all lifts.

Collaboration with Project Teams

Strong communication between operators, supervisors, and project managers is reinforced through Bigfoot’s support. By providing practical input on planning, site layout, and scheduling, we help teams maintain discipline and accountability.

Partnering with a company that emphasises structured processes and operational alignment strengthens site safety culture. Teams benefit when planning, logistics, and hands-on coordination come together to protect people, schedules, and equipment.

Conclusion

Safety on tower crane sites develops through consistent attention to daily practices. Small choices made by operators, riggers, supervisors, and project teams accumulate to create safer environments for everyone involved. Taking the time to follow protocols, perform inspections, and communicate clearly reinforces a culture where risks are managed proactively. Regularly reviewing habits and processes helps crews identify opportunities for improvement before issues arise. When safety is treated as a shared professional standard rather than a task to check off, the entire site benefits. Consistent habits, thoughtful planning, and disciplined execution ensure safer lifts today and set the tone for responsible operations in the future.