Lifting beams play a key role in heavy lifting, helping businesses move large loads with stability. These beams connect to a crane or hoist, creating multiple lifting points that distribute weight evenly. This setup reduces load and lifting equipment stress, making operations safer and more efficient. Choosing the right equipment for the job protects workers and prevents unnecessary strain on lifting gear. Understanding how lifting beams work helps businesses maintain safe operations while maximizing productivity.

What is a Lifting Beam?

A lifting beam is a horizontal structure designed to support and stabilize heavy loads during lifting operations. This equipment connects to a crane or hoist, providing multiple lifting points that help distribute weight evenly. Unlike a simple hook or sling, a lifting beam reduces stress on the load and lifting mechanism, improving safety and efficiency.

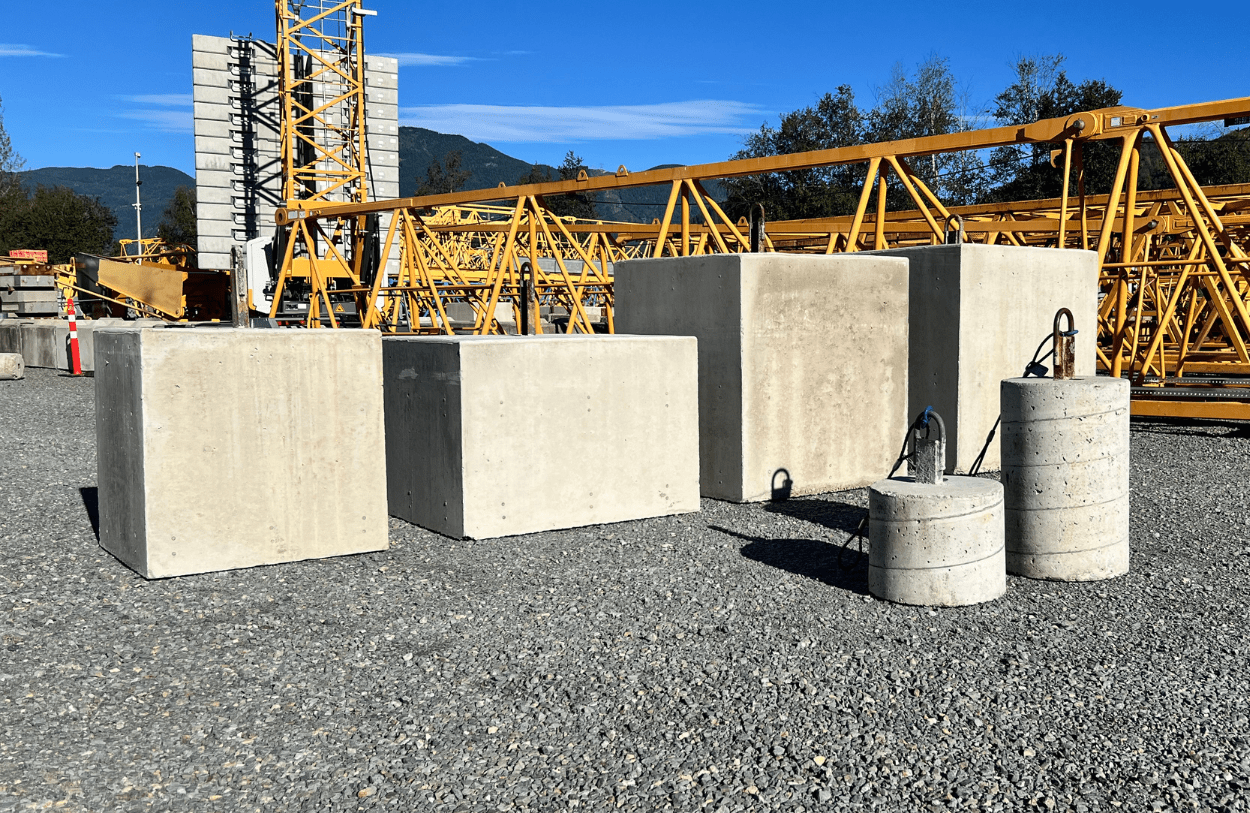

Industries that deal with large, heavy, or oddly shaped materials rely on lifting beams for secure handling. These beams are commonly used in construction, manufacturing, shipbuilding, and warehousing. Moving steel plates, precast concrete, heavy machinery, and fragile materials becomes much safer when the weight is balanced across multiple attachment points.

Key Components and Materials Used

A lifting beam typically consists of a strong central beam with connection points for slings, hooks, or other rigging equipment. The design varies depending on the load requirements. Some beams have fixed lifting points, while others feature adjustable attachments to accommodate different load sizes and shapes.

Steel is the most common material used in lifting beams due to its strength and durability. It can withstand heavy loads without bending or warping. Aluminum beams are also available for applications where weight reduction is a priority. These beams provide a lighter alternative while maintaining a high level of strength.

Safety plays a major role in lifting beam design. Manufacturers engineer these beams to handle specific weight capacities, ensuring they perform well under expected loads. Engineers consider factors such as load weight, balance, and environmental conditions to create reliable lifting solutions. Using the right beam for each job reduces strain on lifting equipment and prevents accidents caused by unbalanced loads.

Common Industries Where Lifting Beams Are Used

Construction Sites

Lifting beams are essential for moving concrete slabs, steel beams, and prefabricated structures. Large sections of buildings or bridges often require precise lifting to fit into place correctly. A welldesigned lifting beam provides the control needed for these operations.

Manufacturing Facilities

Factories rely on lifting beams for assembling and transporting heavy machinery. Many industrial machines contain delicate components that require careful handling. A lifting beam allows workers to move equipment safely without causing damage.

Shipyards

Shipbuilding requires lifting large metal plates and ship components that are heavy and difficult to manage with standard lifting methods. A lifting beam ensures these materials remain stable during transport, reducing the risk of damage.

Warehouses and Logistics

Storage and distribution centers use lifting beams to handle oversized products and materials that need careful positioning. Some lifting beams come with special attachments for moving drums, coils, or fragile items that require extra support.

Why Are Lifting Beams Used?

Using a lifting beam minimizes the risk of damage to materials and ensures better control during hoisting operations. Industries such as construction, manufacturing, and shipping rely on lifting beams to move everything from steel plates to fragile machinery parts. These beams provide advantages over basic slings or direct crane lifts by improving weight distribution, versatility, and overall workplace safety.

Load Distribution Benefits in Lifting Operations

A lifting beam ensures that weight is evenly spread across multiple lifting points. This distribution reduces stress on individual rigging components and prevents uneven force from being applied to the load. When lifting a long or flexible load, such as a steel plate or a large glass panel, using a single attachment point can cause bending, warping, or even breakage. A lifting beam eliminates this issue by securing the load at several points, keeping it stable throughout the lifting process.

Load distribution also protects the crane or hoist from unnecessary strain. A poorly balanced load can cause tilting or sudden shifts, leading to accidents or equipment damage. Lifting beams help prevent these risks by providing a controlled and balanced lift.

Versatility in Handling Different Types of Loads

A lifting beam can be designed for a wide range of applications, making it one of the most adaptable lifting solutions available. The ability to adjust lifting points or add specialized attachments makes it suitable for handling various shapes and sizes. Some lifting beams come with adjustable lifting points, allowing operators to accommodate loads of different widths. Others include features like rotating hooks or clamps designed for specific materials, such as concrete slabs, machinery, or shipping containers. This flexibility makes lifting beams an excellent choice for operations that require handling different types of materials throughout the day. Instead of switching between multiple lifting tools, workers can rely on a single lifting beam to handle a variety of tasks.

Safety Advantages Over Other Lifting Methods

Lifting operations always come with risks, but using the right equipment reduces the chances of accidents. A lifting beam provides several safety advantages over basic slings or direct crane hooks.

- Better Load Stability – A lifting beam minimizes load swinging and tilting, reducing the risk of dropped loads or collisions with nearby structures.

- Reduced Rigging Failures – Spreading the weight across multiple attachment points lowers the stress on slings and hooks, preventing sudden equipment failures.

- Improved Control – Operators have more control over the lifting process, allowing for smoother movements and more precise positioning of heavy loads.

- Lower Risk of Load Damage – Delicate or fragile items benefit from even weight distribution, which prevents bending, cracking, or crushing.

Workplace safety regulations often require secure lifting methods, especially for oversized or heavy materials. Using a lifting beam helps companies meet these safety standards while protecting workers and equipment.

Lifting Beam vs. Spreader Beam: Key Differences

Lifting beams and spreader beams are two common solutions used in different lifting scenarios. Each has distinct characteristics that determine how they distribute weight and handle various loads. Understanding their differences helps in selecting the right tool for a specific application.

Design and Function

Lifting beams are horizontal structures designed to support a load from a single central attachment point on top. This configuration allows them to be used in environments where height restrictions limit lifting options. They are typically constructed from steel or aluminum and can accommodate a variety of lifting attachments such as hooks, slings, or shackles. The structure of a lifting beam ensures that the weight of the load is supported directly beneath the beam, making it well-suitable for situations where headroom is limited and a compact lifting solution is needed.

Spreader beams, on the other hand, use a different structural design to distribute weight. Instead of suspending a load directly below, a spreader beam separates lifting points by using two or more attachment points at the top, typically connected to a crane or hoist. This setup creates a wider lifting area, reducing stress on the load and preventing deformation. Spreader beams are particularly useful when lifting long or delicate objects, such as pipes, panels, or prefabricated sections of buildings, as they minimize bending forces that could cause damage.

Load Distribution Differences

Load distribution is one of the biggest differences between these two beams. A lifting beam holds the load from a single central point, which can concentrate weight in one area and require additional stability measures to prevent tilting. Spreader beams, in contrast, distribute forces evenly across multiple lifting points. This design provides better load control and reduces the risk of shifting during a lift. When lifting operations require stability over longer distances, spreader beams provide a practical solution by balancing weight more effectively.

Use Case Scenarios

Selecting the right beam depends on several factors, including the type of load, available headroom, and lifting requirements. Lifting beams excel in tight spaces where height is limited, such as warehouses or manufacturing plants with restricted ceiling clearance. They are also useful when handling multiple lifting points is not an option. Spreader beams work best for lifting large, fragile, or heavy items that need evenly distributed weight to avoid structural damage. Industries like construction, shipping, and aerospace often rely on spreader beams to lift oversized equipment or delicate components with precision.

Cost, Durability, and Efficiency

Cost and durability also play a role in choosing between these two options. Lifting beams tend to have a simpler design, which often makes them more affordable and easier to maintain. Their durability allows them to withstand repeated heavy lifting in demanding environments. Spreader beams, with their extended structure and multiple attachment points, can be more expensive and require additional rigging components. However, their ability to handle specialized lifting tasks justifies the investment in many industries.

How Center of Gravity Affects a Lift

The center of gravity (CG) plays a critical role in lifting operations. It refers to the point at which a load’s weight is evenly distributed. Understanding the center of gravity helps to maintain balance and ensure safety. This section covers the influence of the center of gravity on lifts, the risks of improperly balanced loads, and techniques to determine and adjust the CG.

The Importance of Center of Gravity in Lifting Operations

In any lifting operation, the center of gravity of the load significantly impacts how the load behaves during lifting. When a load is lifted, the lifting equipment must accommodate the entire weight at this specific point. If the CG is not properly accounted for, the load may shift, causing instability. This imbalance can lead to dangerous situations, including tipping, swinging, or even dropping the load. A well-balanced load, on the other hand, provides a steady lift and reduces the chances of accidents or equipment damage.

How an Improperly Balanced Load Affects Safety and Performance

When a load is not balanced properly, it puts unnecessary strain on the lifting equipment. For example, if the central of gravity is off-center, the load may sway or twist during the lift, making it harder to control. This can increase the risk of accidents such as the load slipping or the lifting equipment tipping over. Improperly balanced loads are also more likely to result in misalignment with the lifting points, further straining the equipment and potentially causing long-term damage.

In industrial settings, these safety risks are not just a matter of equipment failure; they can lead to serious accidents that might injure workers or damage property. Additionally, lifting operations become less efficient when a load is poorly balanced, as more time and resources are required to adjust and correct the situation. In these cases, safety becomes directly tied to the smoothness and efficiency of operations.

Techniques for Determining and Adjusting the Center of Gravity

Determining the center of gravity is crucial to a successful lift. Several techniques can help to ensure that loads are properly balanced before they are lifted. First, understanding the dimensions and weight distribution of the load is essential. This can be done through calculations or using specialized tools that measure the CG in real-time. In many cases, the CG is located at the center of the object, but for irregularly shaped or asymmetrical loads, it may require a more detailed analysis.

A common technique to adjust the center of gravity is repositioning the load on the lifting device. This can include moving the load closer to the lifting point or adjusting the attachment points on the load. For more complex loads, additional equipment, such as counterweights or adjustable slings, can help reposition the load and shift its CG to a safer, more balanced location.

In some cases, specialized lifting beams or spreader bars can be used to adjust the distribution of weight across multiple points, helping to evenly distribute the load’s weight and minimize the risk of tipping. Ensuring that the center of gravity is adjusted before lifting begins is key to a successful operation.

How Center of Gravity Affects Balancing

Lifting heavy loads requires careful consideration of many factors. Among these, understanding how the center of gravity (CG) impacts balancing is fundamental to safe and effective operation, particularly when using spreader beams. Knowing how CG influences lifting operations can significantly improve load stability and reduce the risk of accidents. Let’s break down how the center of gravity affects balancing, especially when it comes to spreader beams.

The Role of Center of Gravity in Lifting

When lifting a load, maintaining proper balance is key to a smooth and controlled movement. The load’s CG affects how forces are distributed during the lift. If the CG is not aligned with the lifting point, it can cause the load to tilt, shift, or become unbalanced.

A load that is not properly balanced may result in unpredictable movements, increasing the chance of accidents or equipment failure. Even when using a spreader beam to distribute the load’s weight, an incorrect calculation of the CG can undermine its effectiveness, leading to unsafe lifting operations. Understanding the relationship between the load’s CG and its position during lifting helps operators ensure that the load remains stable and secure.

Spreader Beams and Load Stability

A spreader beam is designed to distribute the weight of a load across multiple points to enhance balancing and stability. When lifting large or heavy objects, the spreader beam allows the weight to be evenly spread out over several points, rather than all the force being concentrated in a single lifting point. This balancing minimizes the risk of overloading any one part of the beam and reduces the chance of the load becoming unbalanced.

However, even with a spreader beam, the load’s CG must be properly calculated. If the CG is not directly aligned with the beam’s lifting points, it could cause the load to shift during the lift. The spreader beam will not be able to compensate for an incorrectly balanced load, and the result could be disastrous. Therefore, understanding and managing the CG is just as critical when using spreader beams as it is with other lifting equipment.

Impact of Off-Center Loads

When the CG is off-center, it creates an imbalance that can be dangerous during the lift. For example, if the load’s CG is closer to one side, that side will carry more of the weight. This can lead to the load tipping, which is particularly hazardous when lifting high or large loads. Even slight imbalances can cause the load to swing uncontrollably, putting both operators and nearby workers at risk.

Properly positioning the CG is even more critical when lifting irregularly shaped objects. For example, long beams, pipes, or machinery can have CGs that are hard to predict. Using a spreader beam helps in such situations by giving multiple lifting points to distribute the load more evenly. But, if the CG is miscalculated, no amount of equipment can make up for the imbalance.

How to Calculate the Center of Gravity

Calculating the center of gravity might sound technical, but it’s necessary for safe lifting. It involves determining where the weight of the load is concentrated. For regular shapes, like a box, the CG is often at the geometric center. But for irregularly shaped objects, you may need to use a more detailed approach, such as finding the balance point or calculating the CG based on the object’s mass distribution. In many lifting operations, it’s helpful to use a professional service or software to calculate the CG, particularly for complex loads. Doing so ensures that you’re lifting the load safely and efficiently.

Types of Lifting Beams and Spreader Beams

Choosing the right beam for a specific job is crucial for maintaining safety, improving efficiency, and ensuring precise control over the lifting process. In this section, we will discuss various types of lifting beams, including fixed and adjustable lifting beams, standard and modular spreader beams, as well as crane and hoist beams.

Fixed Lifting Beams vs. Adjustable Lifting Beams

Lifting beams are used to support and balance loads, but they come in two primary types: fixed and adjustable. Fixed Lifting Beams are designed for specific lifting operations where the load requires a steady and consistent lifting point. The distance between the lifting points is fixed, making this type of beam ideal for situations where the lifting load does not change often. These beams are simple, durable, and often used in environments with predictable lifting requirements. Since the lifting points are set, fixed lifting beams provide a reliable and safe method of handling heavy or loads.

On the other hand, Adjustable Lifting Beams offer more flexibility. The lifting points can be adjusted along the beam, allowing the operator to adapt the beam to different load types and lifting conditions. This adaptability makes adjustable lifting beams perfect for handling a wide range of loads, especially when the lifting height or load configuration varies. These beams typically come with a mechanism, such as pins or bolts, that allows the operator to reposition the lifting points. While adjustable lifting beams provide greater versatility, they may require more maintenance due to the moving parts.

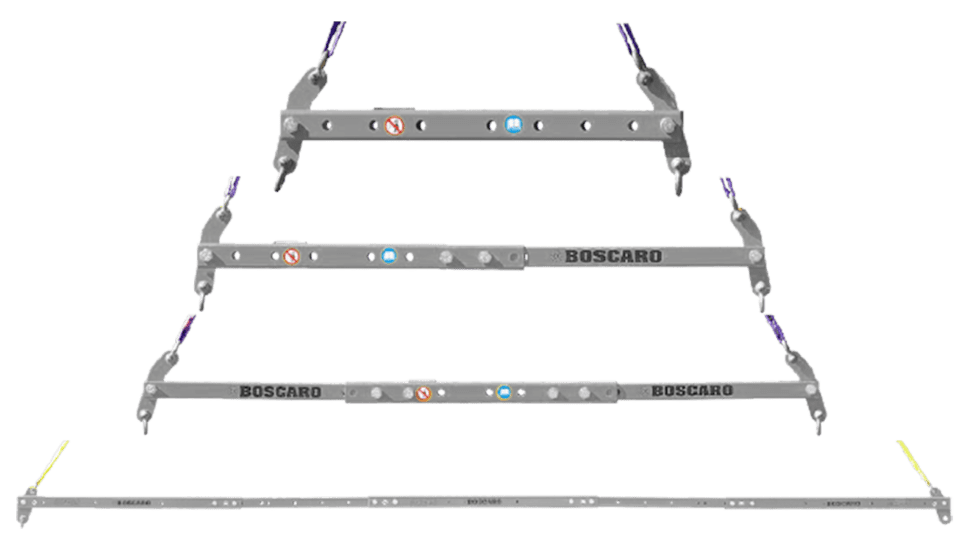

Standard vs. Modular Spreader Beams

Spreader beams are commonly used to lift wide loads or loads that require stability across multiple lifting points. They come in two main types: standard and modular.

Standard Spreader Beams are simple, rigid beams that connect to lifting points on either end. These beams provide stability for loads by preventing them from swaying or shifting during the lift. Standard spreader beams are built to specific dimensions and weight capacities, making them ideal for general lifting tasks that don’t require adjustments. They are sturdy, reliable, and easy to use, but they are typically designed for specific types of lifts and may not be suitable for all lifting scenarios.

Modular Spreader Beams, on the other hand, offer greater flexibility and customization. These beams consist of multiple components that can be assembled and configured to meet the specific needs of the load being lifted. Modular spreader beams are highly adjustable, allowing the operator to change the length, width, and configuration to suit different lifting situations. This type of beam is often used for heavy-duty lifting, where the load needs precise balancing and control. Modular beams are ideal when lifting requirements change frequently or when there is a need to lift unusually shaped or oversized loads.

Crane Beams, Hoist Beams, and Their Specific Applications

Crane Beams are typically used in overhead crane systems. These beams are mounted on a crane to support and distribute the load across a wide area. Crane beams are usually designed to handle heavy loads that are lifted and moved horizontally. These beams come in different configurations, including single-girder and double-girder systems, and are tailored to support specific types of loads. They are widely used in industrial settings, such as factories, warehouses, and construction sites, where large, heavy items need to be moved across significant distances. The crane beam works with the crane’s hoist mechanism to provide the necessary lifting force and movement control.

Hoist Beams are typically used in combination with hoists, which are machines used to lift and lower loads. The hoist beam serves as a support structure for the hoist and the load, allowing the hoist to move smoothly during the lifting process. Hoist beams are often used in more compact or specialized settings where precision and manoeuverability are important. They are ideal for situations where the load needs to be lifted vertically, and where the lifting process requires careful control over height and position. Hoist beams are often found in workshops, maintenance areas, and smaller warehouses where precise lifting and lowering are necessary.

Both crane beams and hoist beams are essential for lifting operations, but each type has unique features that make them suitable for different tasks. Crane beams are more suited to heavy-duty horizontal lifting, while hoist beams excel in smaller, more precise vertical lifting operations.

Choosing the Right Lifting or Spreader Beam

The right beam ensures load stability, enhances safety, and contributes to the overall efficiency of the task. Several factors should be considered to make an informed decision when choosing a beam, such as load type, weight capacity, and the lifting environment. Additionally, it’s important to match the beam selection with crane specifications and adhere to safety and compliance guidelines. Let’s explore these factors in more detail.

Factors to Consider: Load Type, Weight Capacity, and Lifting Environment

Load Type plays a significant role in determining which lifting beam to choose. Different beams are designed to handle various load shapes and sizes. Some beams are ideal for lifting irregularly shaped loads, while others may be more suited to standard or uniform loads. Consider the geometry of the load: a spreader beam, for example, is often best for lifting wide or bulky items, as it distributes the weight evenly across multiple lifting points. For longer or awkward loads, a lifting beam might be more appropriate to provide better control.

Weight Capacity is another critical factor in beam selection. It’s essential to know the weight of the load you’re lifting to ensure the beam can safely support it. Exceeding the beam’s weight capacity can lead to accidents, including beam failure or unsafe load movement. Always account for the total weight of the load, including any rigging, and compare this with the rated capacity of the beam. This information is typically available from the manufacturer, and it should be adhered to without exception to avoid dangerous situations.

Lifting Environment also impacts beam choice. Consider whether the lifting operation will take place indoors or outdoors, on rough terrain, or in a confined space. If you’re working in a confined area, you may need a beam that offers better maneuverability and flexibility. Outdoor environments may require beams that are more durable and resistant to the elements. Additionally, extreme temperatures or exposure to chemicals can also affect the performance of certain materials used in the construction of lifting beams. Ensuring the beam is compatible with the environment will contribute to both performance and longevity.

How to Match Beam Selection with Crane Specifications

When selecting a lifting or spreader beam, it’s vital to match it with the specifications of the crane you’re using. Different cranes have varying lifting capacities, reach, and operational limits. Ensuring that the beam is compatible with the crane is essential for a smooth and safe operation.

Check the crane’s load capacity to confirm that it can handle the combined weight of both the beam and the load. If the beam is too heavy for the crane, it may exceed the crane’s operational limit and compromise safety. Additionally, consider the crane’s lifting height and reach. The beam should align with the crane’s lifting range to avoid overloading or inefficient operation.

Other considerations include the crane’s hook height and sling attachment points. The lifting beam needs to be able to connect to the crane’s lifting points securely and stably. Make sure the lifting beam’s lifting points are compatible with the crane’s hook or other attachment mechanisms, ensuring a safe and stable connection during the lift.

Safety and Compliance Considerations

All lifting equipment, including beams, must comply with relevant safety standards and regulations. These may vary depending on the location and type of work being done. In North America, lifting equipment must meet the requirements of organizations such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These regulations set forth guidelines for weight limits, beam construction, and testing procedures to ensure that lifting beams are used safely.

Additionally, it’s essential to conduct regular inspections of lifting beams before each use. Any signs of wear, damage, or deformation should be addressed immediately. Lifting beams should be tested for their load-bearing capacities at regular intervals, and operators should be trained in how to properly handle them to prevent accidents.

Maintaining clear communication among the team members involved in the lifting process is another critical safety measure. Operators should understand the beam’s specifications, including its load capacity and intended use. Only trained personnel should handle lifting operations, and proper signaling should be established to coordinate the movements of the crane and the load.

Finally, ensure that any lifting operation involving beams follows the manufacturer’s recommendations. Each beam comes with its own set of guidelines for use, maintenance, and safety. Adhering to these recommendations will help reduce risks and improve overall safety.

Conclusion

Lifting beams are essential for ensuring safe and efficient heavy lifting operations. They provide stability, distribute load weight evenly, and enable cranes to handle various types of loads effectively. However, safety and proper selection are paramount. Matching the right beam to the project and adhering to safety standards can prevent accidents and improve overall lifting efficiency. At Bigfoot Crane Company, we understand the importance of choosing the right equipment for the job. Reach out to us today, and let us help you select the perfect lifting solution for your needs. Safety and precision are our top priorities.