Hydraulic clamshell buckets are crucial tools in material handling, offering efficiency and precision across various industries. These heavy-duty buckets improve the speed and accuracy of moving bulk materials, making them indispensable in construction and industrial applications. Built to withstand harsh environments, they ensure safe and reliable operation, even in demanding conditions. The design of hydraulic clamshell buckets allows for precise control during loading and unloading, boosting operational efficiency. Their ability to handle large volumes of material while maintaining durability makes them essential for projects requiring accuracy and reliability.

What is a Clamshell Bucket?

A clamshell bucket is a specialized tool designed for efficient material handling. It features two hinged clamshell halves that open and close like a shell, and it grabs, holds, and transfers materials with precision. Clamshell buckets are commonly used for excavating, lifting, and dumping bulk materials like sand, gravel, and waste. These buckets are highly adaptable and capable of handling everything from construction debris to soil and aggregates.

Clamshell equipment plays an important role in moving large volumes of material quickly and safely in industries such as construction, excavation, and material transfer. Whether working on a construction site, clearing waste, or transferring materials at a port, these buckets ensure reliable and efficient operation. Their durability and ability to handle tough materials makes them a key tool in projects requiring precise material handling.

Understanding Hydraulic Clamshell Buckets

Hydraulic clamshell buckets use a hydraulic system to control the opening and closing of the clamshells. This system ensures smooth and precise movement, allowing operators to manage heavy loads efficiently. Hydraulic systems provide a level of accuracy that manual or mechanical methods simply can’t match. Operators can easily control the bucket’s movements, improving the overall speed and effectiveness of material handling. Hydraulic-powered buckets require far less effort than manual operation, reducing fatigue and allowing workers to stay productive longer.

Precision and Efficiency

One of the main advantages of hydraulic systems is their ability to improve precision. The operator can adjust the bucket’s movement in small increments, allowing for delicate tasks like loading materials without causing spills. This precision is crucial, especially when handling valuable or hazardous materials, as it reduces the chance of errors. Furthermore, hydraulic systems increase efficiency by reducing the time needed to perform tasks. Hydraulic clamshell buckets significantly reduce the overall duration when lifting, loading, and unloading bulk materials, making projects move faster.

Applications in Cranes and Excavators

Due to their versatility, hydraulic clamshell buckets are frequently used in cranes and excavators. Crane clam buckets are ideal for lifting and transferring large quantities of material, such as construction debris, gravel, or sand. Their hydraulic capabilities allow for quick, efficient material handling, even in tight spaces. Excavators, on the other hand, rely on hydraulic clamshell buckets for tasks like digging, scooping, and loading materials. Hydraulic systems in excavator clam buckets help achieve the precision needed for detailed operations, such as safely digging in confined areas or lifting specific materials. These applications showcase the flexibility and power of hydraulic clamshell buckets in diverse work environments.

Features of Hydraulic Clamshell Buckets

Below, we explore the key features of hydraulic clamshell buckets highlighting the qualities that make them a top choice for material handling applications.

Wireless Remote Control

One of the standout features of hydraulic clamshell buckets is their wireless remote control capability. Operators can control the bucket 100 feet away, offering improved convenience and safety. This remote control system allows operators to handle materials efficiently without being directly in the danger zone. Whether working with cranes or excavators, the remote control system allows operators to make adjustments from a safe distance. This feature reduces the risk of injury and improves workflow, especially in hazardous or tight environments. The ability to remotely operate the bucket ensures that the operator can maintain full control, regardless of the surrounding conditions, while increasing the overall productivity of material handling tasks.

Battery-Powered Design

Hydraulic clamshell buckets are powered by lithium-ion batteries equipped with an internal charger. This battery-powered design offers multiple advantages, including increased portability and minimal dependency on external power sources. Including an internal charger ensures that the bucket is always ready for use, as the battery can be easily charged on-site.

The use of lithium-ion batteries is particularly beneficial from an environmental standpoint. Unlike traditional fuel-powered systems, these batteries produce fewer emissions and require less maintenance. They also have a longer lifespan, reducing the needed for frequent replacements. This environmentally friendly design aligns with sustainability goals while offering a reliable and efficient power source for heavy-duty operations. As industries look to reduce their carbon footprints, the battery-powered hydraulic clamshell bucket presents a cleaner, more sustainable option for material handling.

Large Capacity and Dumping Zone

Hydraulic clamshell buckets are designed to handle large volumes of bulk materials easily. They are typically engineered with wide, spacious jaws capable of lifting and transferring substantial amounts of sand, gravel, waste, and other materials. The large capacity ensures fewer trips are required, reducing project timelines and increasing overall operational efficiency.

Additionally, the wide dumping zone allows for precise unloading. Materials can be discharged quickly and accurately, which is particularly important in industries like construction, where fast turnover is essential. By eliminating the need for repeated handling or transfers, hydraulic clamshell buckets improve job site productivity and reduce the risk of delays in material processing or transport.

Built for Safety, Strength, and Longevity

Safety is a top priority in any heavy machinery operation, and hydraulic clamshell buckets are built with this in mind. These buckets meet or exceed ASME (American Society of Mechanical Engineers) standards, ensuring that they adhere to industry regulations for safety and performance. Compliance with these standards guarantees that the hydraulic clamshell buckets are designed to handle heavy-duty tasks while maintaining operator safety.

The strength and durability of these buckets come from their robust construction, which is made to withstand continuous use in demanding environments. These buckets feature reinforced structures and high-quality materials that ensure a long service life. Safety features such as automatic locking mechanisms and hydraulic pressure systems also help prevent accidents during operation. The combination of strength, durability, and safety makes hydraulic clamshell buckets ideal for various industries, including construction, marine, and waste management.

Durable Construction for Harsh Environments

Hydraulic clamshell buckets are built to withstand some of the most challenging work environments. The high-quality materials used in their construction are specifically chosen to resist wear and tear, even under the most demanding conditions. Many of these buckets include corrosion-resistant components, crucial in industries where exposure to water, chemicals, and other harsh elements is common.

For instance, in marine or waterfront construction projects, hydraulic clamshell buckets may be exposed to saltwater, which can cause corrosion over time. However, using specialized coatings and rust-resistant components ensures that the buckets remain functional and efficient for years. This durability also makes them suitable for extended continuous operation in construction, excavation, and industrial sites, where reliability is key.

The resilience of hydraulic clamshell buckets is not limited to corrosion resistance. They are designed to perform well even under extreme pressure or heavy usage. Whether in high-temperature conditions or areas subject to intense physical wear, these buckets are built to maintain their performance and extend their operational lifespan.

High Precision and Control

Hydraulic control systems provide hydraulic clamshell buckets with unmatched precision in material handling. The fine-tuned opening and closing mechanisms allow operators to pick up and release materials accurately, even in tight spaces or at heights. This level of control is crucial when handling sensitive materials or working in crowded areas, as it minimizes the risk of spillage and ensures safe unloading.

High precision reduces the chance of accidental overloading, which can compromise safety and efficiency. The ability to control the bucket’s movements in small, deliberate steps enhances operational efficiency and minimizes the risk of improper material handling. Whether lifting large debris from a construction site or transferring waste material into a container, hydraulic clamshell buckets ensure the process is carried out safely and efficiently.

This precision also improves safety by reducing the likelihood of uncontrolled movements. In environments where workers operate nearby, controlling the bucket’s opening and closing in such a fine-tuned manner is critical in keeping the job site secure.

The Role of Hydraulic Clamshell Buckets for Cranes and Excavators

Integration with Cranes

Hydraulic clamshell buckets are designed to integrate seamlessly with cranes, enhancing their material handling capabilities. When combined with a crane, the hydraulic clamshell bucket allows operators to manage large volumes of bulk materials easily. The crane’s lifting power, combined with the precision offered by the hydraulic bucket, ensures that materials such as gravel, sand, or construction debris are moved quickly and accurately. The hydraulic systems offer operators complete control over the bucket’s movements, allowing fine-tuned opening and closing adjustments, even from a distance, through a wireless remote control.

Simplifying Material Handling in Excavators

Excavators are often tasked with handling materials in smaller, more confined spaces. Hydraulic clamshell buckets offer the same precision and control when attached to an excavator. These buckets allow the excavator to pick up and dump materials accurately. In urban construction sites or environments with limited space, hydraulic clamshell buckets reduce the risk of spillage or misplaced loads, making them ideal for precision work. The added hydraulic control helps operators safely manage the material handling process, improving efficiency and safety in confined conditions.

Ideal for Challenging Environments

Integrating hydraulic clamshell buckets with cranes and excavators simplifies material handling in harsh conditions, such as marine or waterfront projects. These systems are designed to withstand continuous use in extreme weather or tough terrains. The hydraulic clamshell bucket’s high durability ensures that material handling remains efficient and reliable even under the most demanding conditions. This level of efficiency and precision improves safety and accelerates project timelines, allowing operations to continue smoothly, even in the most challenging environments.

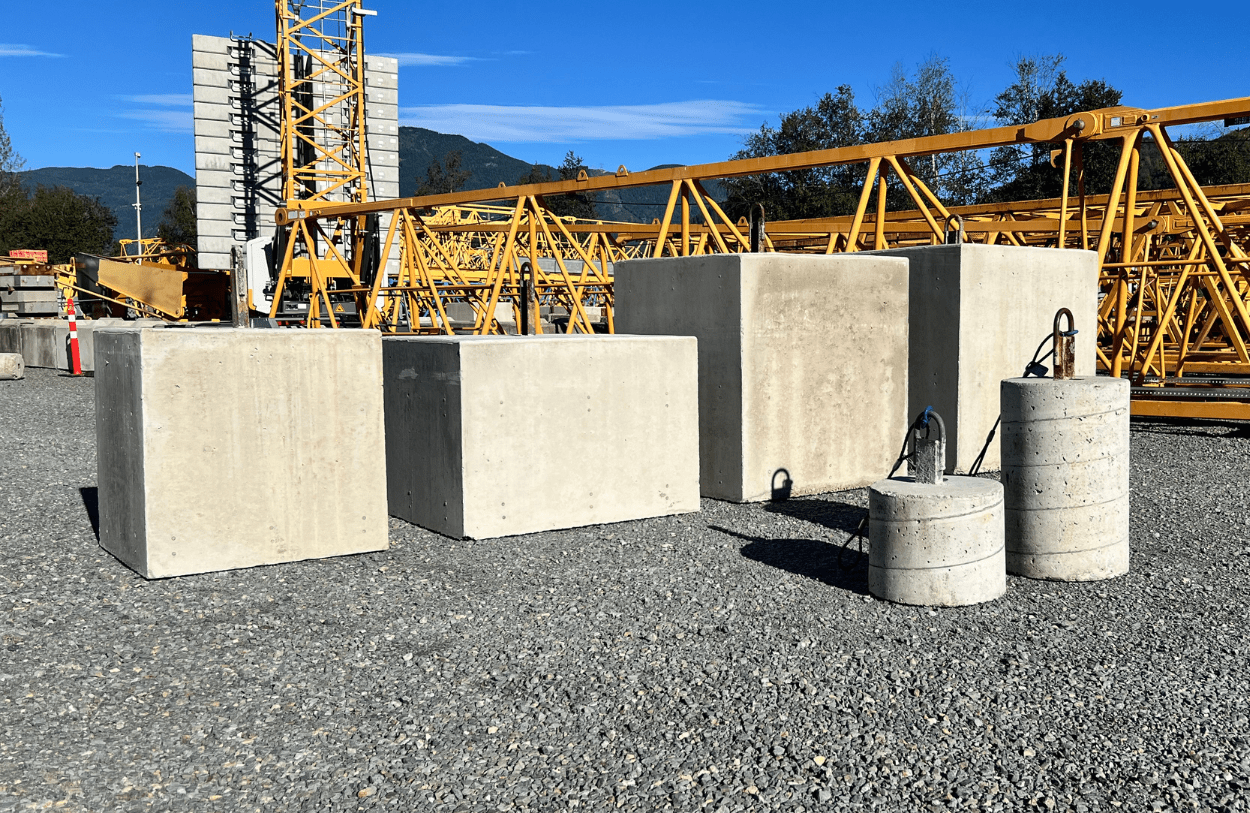

Applications of Hydraulic Clamshell Buckets in Construction and Excavation

In this section, we explore the diverse applications of hydraulic clamshell buckets, showcasing their importance and functionality across various industries for efficient and precise material handling.

Bulk Material Handling

Hydraulic clamshell buckets excel in bulk material handling, making them an invaluable tool on construction sites. These buckets provide a quick and efficient solution for moving large volumes of material, whether sand, gravel, or construction debris. The hydraulic system allows for precise control, making loading and unloading materials from trucks, containers, or other machinery easier. The ability to manage such large quantities reduces project timelines and boosts productivity, especially in high-demand environments.

Waste Management

Managing waste materials during excavation projects can be challenging. Hydraulic clamshell buckets are used extensively for waste removal, helping to load materials such as dirt, rocks, and concrete into disposal trucks. Their ability to handle large loads while maintaining control over the dumping process ensures that waste removal is streamlined. Additionally, the precision offered by the hydraulic controls minimizes the risk of spillage, improving safety and efficiency at the job site.

Marine and Port Operations

Hydraulic clamshell buckets are perfect for marine and port operations and handling materials in waterfront environments. Precision and durability are paramount in these settings, where workers must move bulk materials like coal, salt, or sand in challenging conditions. Whether in shallow waters or exposed to saltwater, these buckets’ corrosion-resistant components ensure reliable performance. The integration of hydraulic systems give operators precise control over the bucket, even in unstable or moving conditions, making them indispensable in the handling of materials on docks and piers.

Heavy Lifting in Demolition Projects

Demolition projects often involve the quick and efficient removal of debris and rubble. Hydraulic clamshell buckets play a vital role in improving demolition workflows. Their precise opening and closing mechanisms allow operators to efficiently handle demolition materials, from concrete blocks to metal scrap. The ability to adjust the bucket’s grip ensures that materials are handled safely, even in challenging demolition environments. This precision reduces risk, increases safety, and speeds up the removal process, helping keep projects on schedule.

Mining and Quarrying Operations

Large volumes of ore, rock, and other materials must be moved efficiently and safely in mining and quarrying. Hydraulic clamshell buckets are perfectly suited for such tasks. Their robust design allows them to handle large quantities of material without compromising on performance or safety. Whether loading trucks or transferring material to other equipment, these buckets improve overall handling efficiency, helping to keep mining operations running smoothly.

Overview of Hydraulic Clamshell Bucket Models

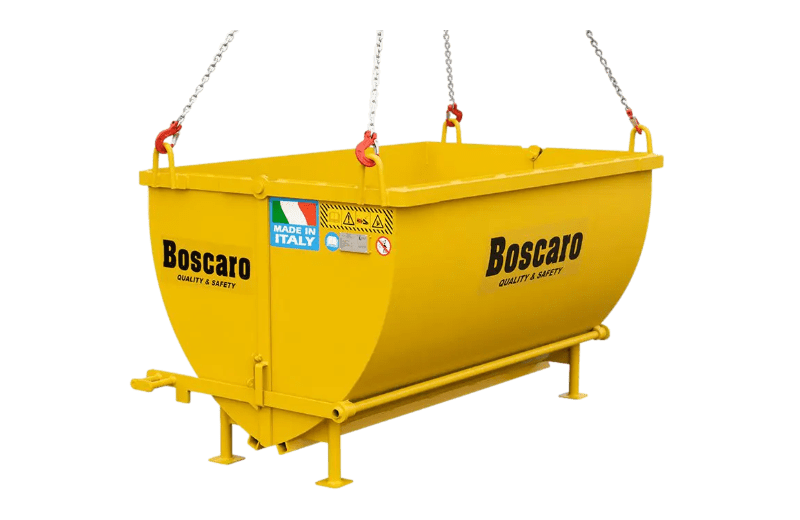

Hydraulic clamshell buckets come in various sizes and models, allowing them to meet different industrial needs. Notable models include the Boscaro A-400DR and A-800DR, which provide reliable options for handling bulk materials with precision.

Capacity and Dimensions

The A-400DR is a compact model designed for lighter lifting and smaller-scale operations. With a capacity of approximately 4 cubic meters, it is well-suited for confined spaces, offering both agility and power for cranes in smaller excavation or construction projects. On the other hand, the A-800DR offers a larger capacity of around 0.8 cubic meters, catering to heavier loads in demanding environments like large-scale demolition or marine operations.

Capacity and dimensions vary across models, allowing users to choose the most suitable size based on their material handling needs. For example, smaller buckets may have lighter capacities, ranging from 500-800 kg, while larger models can exceed 4,000 kg, depending on the specific design and features.

Customization Options

Customization options also play a significant role in tailoring hydraulic clamshell buckets to specific tasks. Manufacturers provide various adaptations, such as bucket depth, width, and the choice of materials, to accommodate specific environments, whether handling waste, sand, gravel, or heavier materials. This adaptability ensures that industrial users, including crane operators, have the right tools for the job, improving efficiency and safety.

Choosing the Right Size for Your Needs

Choosing the appropriate hydraulic clamshell bucket for crane applications requires understanding the load capacity, working environment, and frequency of use. Customization options further allow for a perfect match to specific tasks in industries like construction, demolition, and marine operations.

Choosing the Right Hydraulic Clamshell Bucket for Your Project

In this section, we’ll explain key factors to consider when choosing the right hydraulic clamshell bucket. This will ensure that it meets your project’s needs while optimizing performance and efficiency.

Capacity and Size Considerations

When selecting a hydraulic clamshell bucket, size and capacity play a significant role in ensuring efficiency. It is important to choose a bucket that can comfortably handle the material’s volume and weight. Opting for a bucket that is too small might require multiple trips, slowing down productivity. Conversely, a bucket too large for the task can lead to overloading or difficulty maneuvering. Consider both the material types and the amount you plan to move to ensure smooth operation and avoid unnecessary delays.

Compatibility with Cranes and Excavators

Compatibility between the hydraulic clamshell bucket and the machinery used is essential. A bucket that fits a specific crane or excavator can ensure seamless operation and prevent unnecessary mechanical stress. Mismatched equipment can result in poor performance, risk of damage, and even operator safety hazards. Check specifications for mounting options and attachment systems before purchasing, ensuring that your equipment is up to the task.

Customization Options

At Bigfoot Crane Company, we offer customizable features tailored to project requirements. Customization can include bucket sizes, attachment configurations, and materials designed to withstand specific environmental conditions. If your project requires specialized features, such as a particular gripping mechanism or a reinforced bucket for heavy-duty lifting, customized solutions are available to meet those needs. Customization allows for optimized performance and enhanced worksite efficiency.

Material Type and Handling Requirements

Different materials require different bucket designs. If you’re handling loose, bulk materials like gravel or sand, you might need a larger, more open bucket for quicker unloading. On the other hand, smaller, more compact buckets are better suited for demolition debris or materials that require more controlled handling. Understanding your material handling requirements will help you select the right hydraulic clamshell bucket to improve productivity and safety.

Environment and Working Conditions

Consider the working environment when selecting a bucket. Construction and excavation sites can have harsh conditions, such as high temperatures or exposure to corrosive substances. Hydraulic clamshell buckets with protective coatings or corrosion-resistant features ensure durability and longer service life, even in challenging environments. Choosing a bucket designed to withstand specific environmental factors is an investment in reliability and operational efficiency.

Why Choose Bigfoot Crane Company for Clamshell Buckets?

At Bigfoot Crane Company, we prioritize high-quality hydraulic clamshell buckets and under-the-hook accessories. Here is why you should choose us:

Proven Durability and Performance

Our customers consistently share positive feedback about our clamshell buckets’ exceptional durability and performance. Our products are built to last no matter the challenge. Reliability in every bucket ensures that your project stays on schedule and operates smoothly.

Expert Customer Support

Choosing the right equipment doesn’t need to be overwhelming. We are here to help guide you through the selection process, offering expert support tailored to your needs. Our team is always available to answer any questions and provide assistance to ensure you make the right choice for your project.

Fast and Reliable Delivery Across North America

Getting your equipment when you need it matters. Bigfoot Crane Company guarantees fast and reliable delivery across North America, minimizing downtime and ensuring your project stays on track. We understand that timely delivery is crucial, so we ensure your hydraulic clamshell bucket reaches you efficiently.

Conclusion

Hydraulic clamshell buckets significantly improve material handling precision and efficiency, making tasks quicker and safer. Their ability to handle large volumes of material with fine control reduces spillage and enhances productivity. At Bigfoot Crane Company, we are committed to providing expert solutions that suit your project’s unique needs. Contact us today if you’re looking for reliable and durable clamshell buckets. Our team is ready to help you select the best equipment for your requirements and ensure your operations run smoothly. Let us be a part of your success!