In the realm of construction, tower cranes are pivotal, soaring over city skylines and orchestrating the meticulous assembly of skyscrapers, apartment buildings, and large-scale infrastructure projects. These mechanical giants are not only integral to modern construction but also emblematic of human ingenuity in engineering. This blog aims to unravel the complexities of tower cranes, exploring their mechanics, functionality, and their crucial role in construction operations.

Understanding the Basics: What is a Tower Crane?

Tower cranes are a type of crane that consists of several key components: the base, the mast (or tower), the slewing unit, the working arm (jib), the counter-jib, and the operator’s cab. They are designed to offer incredible lifting capabilities and reach heights that are essential for constructing buildings.

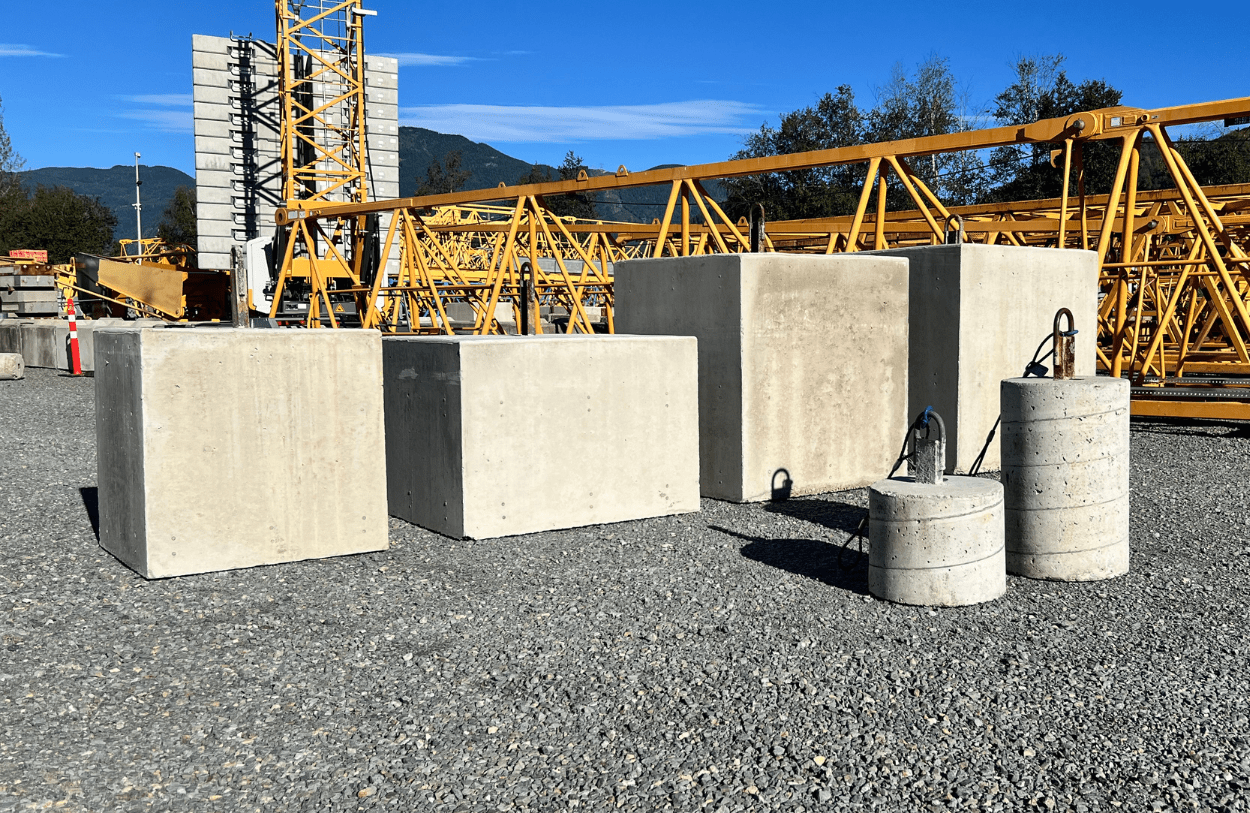

The base of the crane is typically anchored to a large concrete pad that supports the crane. The mast extends from this base, giving the crane its height. Attached to the top of the mast is the slewing unit, which allows the crane to rotate 360 degrees. The jib extends horizontally from the slewing unit, and on the opposite side, the counter-jib holds counterweights, typically concrete blocks, that balance the crane’s load. The operator’s cab sits just above the slewing unit, providing the operator with a comprehensive view of the site and complete control over the crane’s movements.

The Mechanics of Lifting: How Tower Cranes Lift Heavy Loads

Tower cranes are marvels of engineering that can lift up to 18 tons at a time and reach up to 265 feet in height. The secret to their lifting power lies in the mechanism known as the hoisting winch, which controls the up and down movements of the load with the help of a wire rope and a hook.

The trolley and hoist work together to manage the load. The trolley moves the load inward and outward along the jib, while the hoist raises and lowers the load by winding and unwinding the rope on a drum. This coordination allows the crane to position the load precisely on the construction site, an essential feature when placing heavy materials like steel beams and concrete slabs.

Stability and Safety: Ensuring Crane Operations are Secure

The stability of a tower crane is paramount, given the heights and weights involved. Engineers ensure stability through careful calculation of the crane’s counterweights, which must be sufficient to offset the tipping force generated by the load. The design of the mast and the attachment of the crane’s arms are also critical in distributing the forces that act upon the crane during operation.

Safety measures are rigorous in crane operations. Modern tower cranes are equipped with load moment indicators (LMI), which automatically prevent the crane from operating outside of its safe lifting capacity. Additionally, anemometers measure wind speed to ensure that it does not exceed safe operating limits, as high winds can destabilize the crane.

The Role of Tower Cranes in Modern Construction

Tower cranes are indispensable in constructing high-rise buildings. Their ability to lift heavy loads to great heights, combined with their relatively small footprint on the ground, makes them ideal for urban construction sites where space is limited. They are also instrumental in constructing bridges, power stations, and large ships, showcasing their versatility in various engineering fields.

In addition to their practical capabilities, tower cranes contribute significantly to worksite efficiency. They can be erected and dismantled relatively quickly, allowing them to move from one project to another with minimal downtime. Their ability to work at high speeds and with precise accuracy reduces overall construction times, thereby saving on project costs.

Learn more about different types of cranes HERE.

Conclusion: The Giants of the Construction World

Tower cranes are more than just tools; they are the heart of major construction projects, pumping materials across the architectural canvases of cityscapes. Their design and operation reflect the peak of engineering excellence, combining mechanics, physics, and the utmost concern for safety to achieve remarkable feats in construction.

As urban landscapes continue to grow vertically, the role of tower cranes will only become more prominent. Understanding how these cranes work is not just about appreciating the mechanics but also about recognizing their contribution to shaping the modern world. Whether it’s a new skyscraper, a bridge spanning a river, or a new cultural landmark, tower cranes are behind the scenes, lifting not just materials but the very skyline of our cities into the future.

More About Tower Cranes – The Liebherr 125 EC-B 6

The Liebherr 125 EC-B 6 is part of the EC-B series known for its efficiency and safety features. This model is particularly noted for its robust construction and versatility, making it ideal for both urban and large-scale industrial construction projects. Its design facilitates ease of assembly and transport, enhancing overall operational efficiency on construction sites.

Maximum Hook Height: 59 meters

Maximum Lifting Capacity: up to 6,000 kg

Maximum Radius: 58 meters

Maximum Capacity at Maximum Radius: 1,600 kg

For those interested in more detailed specifications or considering this crane for rental or purchase, please contact Bigfoot Crane Company Inc.