Understanding anemometers supports safer operations, better planning, and clearer forecasting across many sectors. These instruments measure wind in ways that influence weather models, aircraft routing, crane safety, and wind turbine performance. Each type of anemometer uses its own method to capture air movement and convert it into readable data. This process helps people interpret changing wind conditions and respond with confidence. Choosing the right device depends on accuracy needs, local conditions, and how data will be used. Knowing the fundamentals makes it easier to apply wind data where it matters most.

What Is an Anemometer?

An anemometer is a device designed to measure the speed of wind and, in many cases, its direction. This instrument provides wind readings that support decision-making in meteorology, aviation, construction, and energy. Understanding the science behind measuring wind helps explain why this tool is so widely relied on. Data from anemometers improves forecasting, supports job site safety, and helps engineers plan for wind exposure. Depending on the model, some anemometers track wind direction using mechanical vanes or advanced sensors. The information collected is used in real time or stored for review, making the tool valuable for both moment-by-moment monitoring and long-term analysis.

Main Types of Anemometers

Anemometers are designed to measure how air moves, and each type works in its own way to serve specific situations. Choosing the right one depends on the level of accuracy needed, the environment it will be used in, and how the data will be applied. This section looks at the five most widely used anemometer types and what makes them useful or limiting.

Cup Anemometers

This classic design features three or four cups attached to arms that spin horizontally when wind passes through. The faster they spin, the stronger the wind. These are often mounted on poles or rooftops.

- Pros: Simple to use, reliable for general wind speed, and useful in long-term outdoor setups.

- Cons: It does not measure direction, and moving parts can wear out over time.

Vane or Propeller Anemometers

These combine a front-facing propeller with a tail that keeps it aligned with wind flow. The speed of the propeller indicates how fast the wind is moving, while the direction is tracked through its rotation.

- Pros: Good for getting both speed and direction, especially at ground level or near buildings.

- Cons: Results can be thrown off if the device doesn’t stay directly in line with wind flow.

Hot-Wire Anemometers

In this method, a wire is electrically heated, and airflow is measured based on how quickly the wire cools. Temperature changes affect voltage, which is translated into wind speed.

- Pros: Very sensitive, well-suited for lab work or low-speed air measurement.

- Cons: Not durable in outdoor settings, and the wire is fragile.

Ultrasonic Anemometers

These instruments use high-frequency sound waves between sensors to track how fast the wind moves and in which direction. Wind affects how long it takes sound to travel, and the system calculates based on these delays.

- Pros: No moving parts, high accuracy, and reliable even in harsh weather.

- Cons: Higher cost and sometimes needs extra software support.

Pressure Tube (Pitot Tube)

This tube measures wind based on the difference in air pressure at the front and sides as wind moves past it. It is most often found on aircraft.

- Pros: Useful for high-speed applications like flight.

- Cons: Doesn’t provide wind direction and can be affected by dirt or ice.

Features to Consider When Choosing One

Anemometers may look simple, but the features they carry can make a major difference in how they perform. Choosing the right device depends on where it will be used, what data needs to be captured, and how frequently the readings will guide decisions. Every feature plays a part in helping the instrument work effectively in real-world conditions.

Accuracy Range

A reliable anemometer should provide data that falls within a clear margin of error. Most manufacturers specify the accuracy range in the product details. When decisions depend on small differences in wind speed, such as in flight safety or research, tighter ranges are better.

Wind Speed and Direction Capabilities

Some models measure speed alone while others can track both speed and direction. Directional data is important in construction, crane operation, and marine work where the angle of wind matters just as much as how fast it’s moving.

Durability and Weather Resistance

Outdoor use demands anemometer parts that resist corrosion, UV damage, and impact from debris. Weatherproof designs are ideal in remote or harsh locations. Units used on coastlines, rooftops, or masts should be sealed tightly to avoid long-term damage from moisture and dust.

Mounting Type

Anemometers may be mounted permanently or carried as handheld tools. Fixed models work well for continuous data at weather stations or on cranes. Handheld versions help in fieldwork where mobility matters. The right mounting type depends on how often and where the instrument will be used.

Digital vs. Analog Output

Digital models provide fast readings with backlit displays and sometimes app connections. Analog versions are often simpler and used where electricity is limited or data logging is unnecessary. The output format should match the workflow.

Smart Features

Modern models can include wireless sync, real-time alerts, or built-in data storage. Alerts can notify users of wind reaching unsafe levels. Wireless systems are useful in construction sites where visibility is low and reaction time matters.

Where and How They’re Used

Anemometers appear in many places, each selected to suit specific needs and environments. Their role in measuring wind provides critical information that keeps people safe and operations efficient across various fields. Understanding everyday anemometer uses gives insight into how wind data supports real-world decisions in safety, design, transportation, and forecasting.

Common Job Site Installations

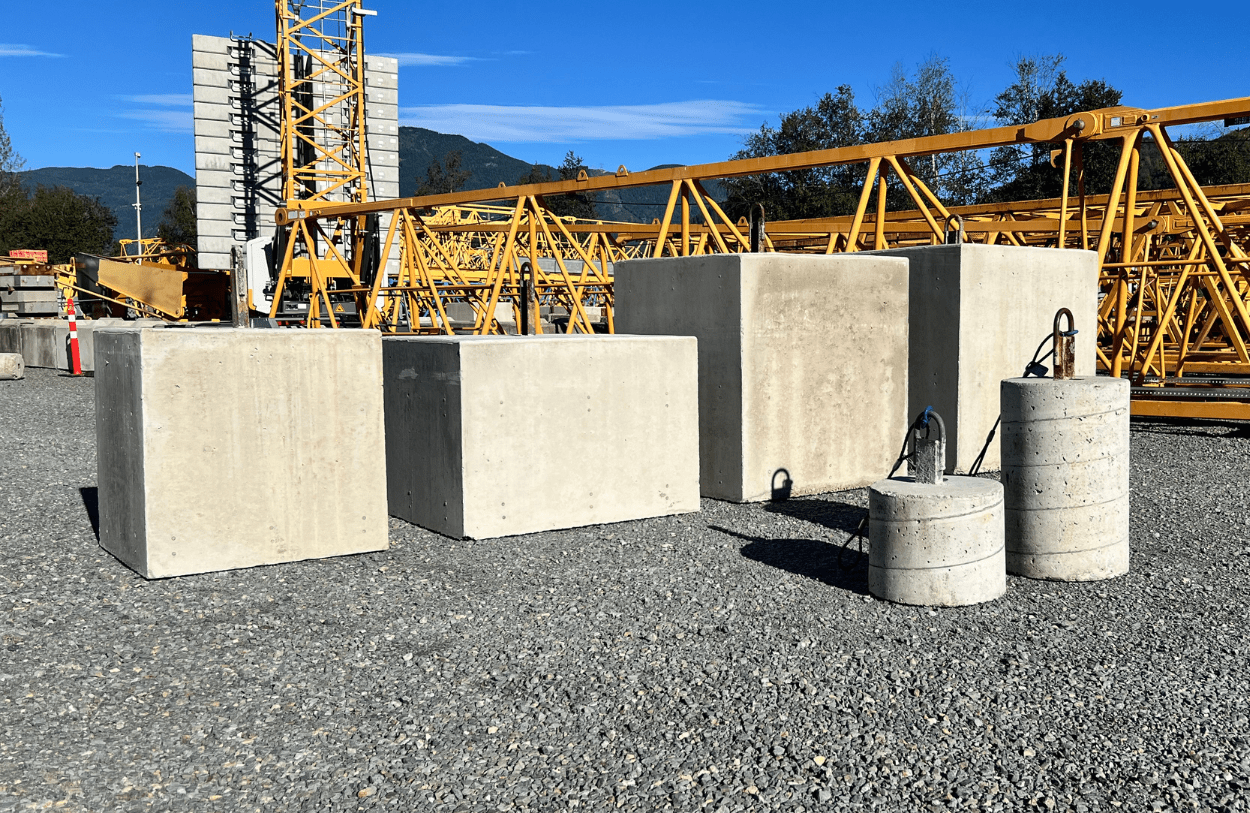

Cranes often have anemometers mounted on or near them to monitor wind conditions constantly. These readings inform operators when winds reach speeds that make lifting risky. Rooftop installations provide data on urban wind patterns and help building managers plan maintenance or assess structural impact during storms.

Use in Weather Stations and Airports

Weather stations rely on anemometers to collect steady wind data that feed local forecasts and support broader meteorological models. Airports use them to guide pilots during takeoffs and landings. Knowing the exact wind speed and direction helps pilots make safer decisions, especially in changing weather.

Marine Environments

Vessels at sea and coastal monitoring stations use anemometers to track wind conditions that affect navigation and safety. Wind measurements assist in route planning and help avoid hazardous areas during storms. Offshore platforms also depend on this data to manage operations and protect workers.

Industrial Safety Systems

Factories and construction sites use anemometers as part of their safety protocols. Sudden changes in wind speed can impact the handling of heavy materials or the stability of temporary structures. Early warnings allow workers to halt risky tasks or secure equipment, reducing accidents.

Wind Energy Sites

Wind farms depend on precise wind data to maximaize turbine efficiency. Anemometers placed at different heights provide insights into wind behavior throughout the day and across seasons. This information helps operators adjust turbine angles and plan maintenance to ensure steady energy production.

Each setting calls for careful placement and sometimes specialized equipment to capture the most accurate wind data possible. These measurements support safety, efficiency, and performance, highlighting how essential anemometers have become in various industries.

Installation and Maintenance Tips

Best Practices for Positioning

Placing anemometers in open spaces free from nearby buildings, trees, or equipment helps capture accurate wind data. Mounting the device at a suitable height avoids ground-level turbulence, allowing wind to flow naturally around the sensor.

Avoiding Obstruction and Interference

Sensors should be positioned away from machinery or structures that can cause wind shadows or turbulence. Selecting a stable mounting point helps reduce vibrations that might lead to inconsistent readings.

Calibration Frequency

Calibration intervals depend on the frequency of use and environmental conditions. Devices operating in harsh or dusty locations may need calibration checks more often to maintain accuracy.

Cleaning and Battery Checks

Regular cleaning removes dirt, dust, and insects that could block sensors or hinder moving parts. Simple wiping and gentle brushing often restores proper function. For wireless or remote units, checking battery levels and replacing them when necessary prevents data interruptions.

Key Tips Summary

- Position sensors in open areas, away from obstructions

- Mount at heights that minimize turbulence

- Avoid locations near machinery or structures causing interference

- Calibrate regularly according to use and environment

- Clean sensors routinely to remove debris

- Monitor and replace batteries as needed

Who Uses Anemometers and Why It Matters

Accurate wind measurement plays a crucial role across many professions. Understanding who uses anemometers and why the data matters helps highlight the device’s importance in everyday safety and productivity.

Professionals Who Use Anemometers

- Meteorologists: Depend on wind data to improve weather forecasts and predict storms.

- Engineers: Rely on accurate measurements when designing buildings, bridges, and other structures to ensure they handle wind forces safely.

- Crane Operators: Monitor wind speeds carefully to avoid accidents during lifts, where sudden gusts can cause hazards.

- Pilots: Require precise wind information for safe takeoffs and landings.

- Farmers: Use wind readings to time spraying and protect crops from damage.

Industry Needs and Device Types

Different fields need various types of anemometers suited to their specific tasks. Meteorologists often use fixed, high-precision instruments within weather stations. Crane operators prefer portable, rugged devices that provide quick on-site readings. Aviation calls for sensors that measure both wind speed and direction in real time. Farmers may choose simpler handheld models for ease of use.

Why Accuracy Matters

The required accuracy depends on how critical wind data is to safety and operations. Reliable measurements support better decisions that increase safety and improve efficiency. Knowing wind strength and direction helps prevent accidents, plan work, and produce trustworthy forecasts that protect people and property.

Conclusion

Looking to upgrade or get started with wind measurement? Bigfoot Crane Company is here to support your goals with reliable, high-performance solutions tailored to your field. Our team offers expert guidance to help you choose the right anemometer based on your environment, application, and data needs. We serve a wide range of industries that depend on accurate wind monitoring. Connect with us today and move forward with tools that deliver precision, consistency, and peace of mind.