Crane pallet forks are key in streamlining material handling across various industries. These attachments are designed to work seamlessly with overhead cranes, offering a dependable way to lift and move heavy loads safely and efficiently. Their adaptability makes them a valuable asset in settings like construction sites, warehouses, and logistics hubs.

One standout innovation is the self-leveling feature found in advanced pallet forks. This technology eliminates the need for constant manual adjustments, ensuring the load remains steady during lifting and transport. It reduces operational risks and saves time, boosting overall productivity.

Crane pallet forks provide the flexibility to handle diverse tasks easily, whether lifting pallets of construction materials or managing irregularly shaped loads. As industries demand safer and more efficient tools, developing auto-leveling crane pallet forks signals a practical solution to meet these evolving needs.

What Are Crane Pallet Forks?

Crane pallet forks are specialized attachments that connect with overhead cranes, allowing operators to lift and transport heavy materials effectively. These tools feature adjustable or fixed forks that accommodate various load sizes, making them suitable for different material handling tasks. Their design ensures stability and safety during lifting operations, even in challenging environments.

Crane lifting pallet forks offer a reliable way to streamline material handling in construction, warehousing, and industrial environments. Their strength, adaptability, and ease of use ensure they remain a vital asset in operations requiring efficient and safe lifting solutions.

Types of Pallet Crane Fork Attachments

There are different pallet crane fork attachments, each suited to different material handling tasks. Choosing the right type of crane pallet fork can make a big difference in efficiency and safety. Let’s look at the most common types.

Fixed Pallet Forks

Fixed pallet forks are designed for simplicity and durability. They have a fixed width, meaning they cannot be adjusted to accommodate different load sizes. Fixed pallet forks are popular in construction and industrial settings and ideal for use when load dimensions remain constant. They are particularly useful for handling standard-sized pallets and materials that do not change in size. Their solid construction ensures reliable performance and minimal maintenance, making them a cost-effective option for many businesses.

These forks are often chosen for their ease of use and straightforward functionality. Since they do not require adjustments, operators can quickly connect them to the crane and begin work without worrying about setting up or resizing the forks. Fixed pallet forks are known for their stability, providing reliable lifting power when handling heavy loads in controlled environments.

Adjustable Pallet Forks

Adjustable pallet forks offer increased flexibility compared to their fixed counterparts. These forks allow the width between the prongs to be adjusted, making them ideal for handling various pallet sizes and shapes.

The versatility of adjustable forks is evident in their ability to move from one task to another without needing different attachments. Operators can adjust the width of the forks manually or, in some models, hydraulically, making the change seamless and quick. This feature is particularly beneficial for industries that frequently handle varying load sizes, as it improves efficiency and reduces the need for multiple types of forks.

Self-Leveling Pallet Forks (Auto-Leveling Technology)

Self-leveling pallet forks are an advanced option that incorporates auto-leveling technology. This technology ensures the forks remain level as the crane moves the load. This feature is particularly valuable when handling uneven or irregularly shaped loads. Auto-leveling technology automatically adjusts the forks’ angle, maintaining the load’s balance during lifting and transport. As a result, there is less need for manual adjustments, reducing the risk of accidents or inefficiencies during operation.

These self leveling crane pallet forks significantly improve safety and productivity, especially when loads shift or are challenging to stabilize manually. Maintaining level positioning throughout the lifting process helps minimize the risk of load slippage or tipping. Operators can focus on the task without constantly adjusting the forks or worrying about the load’s stability. This makes self-leveling pallet forks an excellent solution for a wide range of material handling needs, offering high precision and control.

Benefits of Auto-Leveling Pallet Forks

Auto-leveling pallet forks bring significant improvements to material handling operations. These innovative tools feature auto-leveling technology that helps maintain load stability, improve safety, and boost productivity. Incorporating these pallet forks into your crane system offers many advantages that make material handling easier and more efficient.

Improved Load Balance and Safety

A key advantage of auto-leveling pallet forks is their ability to maintain a steady and balanced load throughout the lifting process. Traditional pallet forks rely on manual adjustments to keep loads level, which can be time-consuming and prone to errors. With self-leveling technology, the forks automatically adjust to maintain the load’s balance, regardless of the crane’s position. This reduces the risk of load shifting, tipping, or falling, which could lead to accidents, equipment damage, or even injuries.

The constant, hands-free adjustment provided by auto-leveling forks ensures that operators can focus on other aspects of their tasks, rather than worrying about balancing the load. It makes material handling safer, reducing the chances of human error.

Enhanced Productivity by Reducing Manual Adjustments

Self-leveling crane pallet forks significantly improve operational efficiency. With traditional pallet forks, operators must make manual adjustments each time the load shifts, especially when lifting or moving heavy or unbalanced loads. These adjustments take time and can slow down the entire process.

Auto-leveling forks eliminate the need for such adjustments. The technology automatically maintains the load’s balance during lifting, saving operators time and allowing them to move materials faster. This results in quicker turnaround times for each task, improving productivity across the board. These pallet forks provide a distinct advantage in environments where efficiency is key, such as warehouses, construction sites, or manufacturing plants.

Telescopic Risers and Adjustable Sliding Forks for Flexibility

Another benefit of auto-leveling pallet forks is their built-in flexibility. Many self-leveling forks are equipped with telescopic risers and adjustable sliding forks. The telescopic risers allow operators to adjust the height of the forks, making it easier to lift materials at various elevations. This is especially useful when lifting materials in tight spaces or when high reach is needed, such as in storage facilities or warehouses with tall shelving.

The adjustable sliding forks add another layer of flexibility. These allow operators to widen or narrow the gap between the forks, making handling different pallet sizes or loads easier. This versatility means fewer tools are needed for different tasks, as a single set of auto-leveling pallet forks can be adjusted to fit a wide range of material sizes.

Compliance with ASME Standards

Auto-leveling pallet forks also comply with the high safety and quality standards set by organizations like the American Society of Mechanical Engineers (ASME). Compliance with these standards ensures the forks are built to handle heavy loads safely and efficiently. These standards cover everything from the material quality and design to the load capacity and safety features.

Choosing self-leveling crane pallet forks that comply with ASME standards provides operators and businesses peace of mind. It helps ensure the equipment meets rigorous safety regulations, lowering the risk of failure or accidents due to malfunctions. Adhering to these standards means operators can be confident in the safety and reliability of their lifter, further enhancing the benefits of auto-leveling technology.

Uses of Crane Pallet Forks

Crane pallet forks are indispensable tools in many industries where lifting, moving, and stacking heavy loads is essential. Below, we explore how crane pallet forks are utilized across these industries and how they improve productivity and safety.

Construction Industry

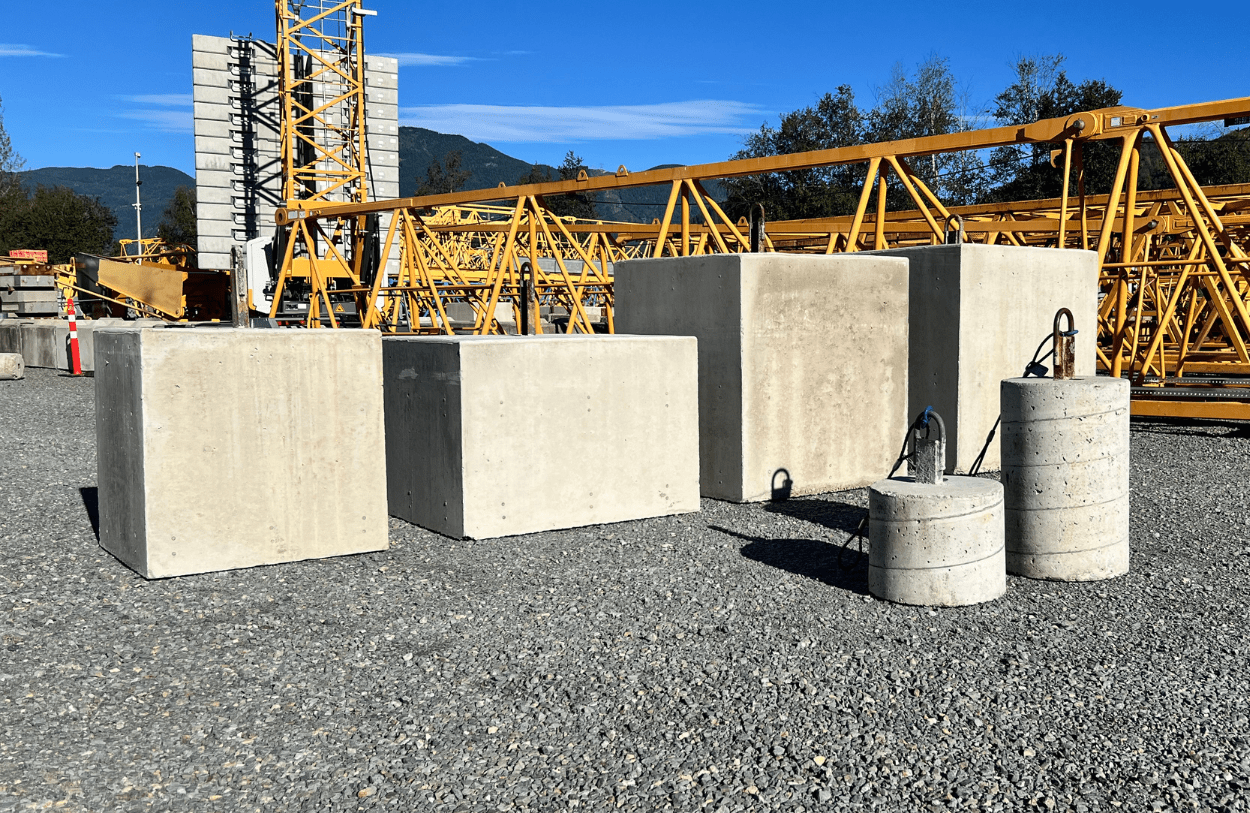

In construction, crane pallet forks are often used to lift and move heavy building materials such as steel beams, concrete blocks, and wooden pallets. These materials can be cumbersome and difficult to handle manually, so crane pallet forks provide an efficient solution to streamline the process.

Crane pallet forks allow workers to safely lift large loads and stack materials at height or on elevated platforms. Their use in construction reduces the need for manual lifting, minimizing the risk of injury. Additionally, they enable workers to handle materials in areas that would be challenging for other lifting equipment to reach, such as high scaffolding or narrow spaces. The ease with which crane pallet forks can be attached or detached from cranes adds versatility, making them a go-to tool on construction sites where multiple tasks are performed.

Warehousing and Storage

Warehouses and storage facilities are all about efficient material management. Crane pallet forks assist in this by enabling the lifting and stacking of pallets, even in hard-to-reach places. Their ability to move heavy items and stack them in high locations helps maximize available storage space.

Crane pallet forks improve the speed of operations in storage operations, making it easier to move goods between shelves and transport them across large warehouse floors. Overhead crane pallet forks allow warehouse staff to retrieve and organize products stored at varying heights quickly. The reduced need for manual labor improves productivity and lowers the risk of injury in fast-paced environments where large quantities of goods are handled daily.

Shipping and Logistics

Shipping and logistics companies rely on quick and effective material handling to keep operations running smoothly. Crane pallet forks are significant in loading and unloading cargo, especially in ports and distribution centers. They are used to lift pallets of goods from trucks, containers, or ships and transport them to their designated locations in warehouses or storage areas.

In logistics, crane pallet forks improve efficiency by reducing the time spent manually handling goods. Their ability to lift large quantities of cargo at once speeds up the loading and unloading process, reducing downtime and improving the overall throughput of logistics operations. These attachments help handle various materials, including retail products, industrial components, and more, making them invaluable in ensuring the smooth flow of goods across the supply chain.

Industrial Manufacturing

Industrial manufacturing plants often deal with large parts, components, and raw materials that need to be moved between different stages of production. Crane pallet forks provide an easy solution for transporting these heavy loads. They can quickly and safely lift large parts or containers of raw materials from storage areas and place them directly into production areas.

Manufacturers use crane pallet forks to speed up material movement across factory floors, ensuring production lines run efficiently. These attachments help minimize delays caused by manual handling and ensure materials are transported precisely where needed. In industries where precision and time management are essential, crane pallet forks reduce downtime and help maintain continuous production processes. Their versatility makes them ideal for handling various sizes of loads, allowing manufacturers to handle both small and large items easily.

Event Setup and Maintenance

Setting up and maintaining large-scale events, such as concerts, festivals, or conventions, often involves handling heavy equipment, staging, and props. Crane pallet forks are commonly used in the event planning industry to move bulky items that would be difficult or impossible to carry manually.

These attachments make the transportation of heavy materials faster and safer at events. Whether lifting sound equipment onto stages or moving large props, crane pallet forks help workers efficiently manage the logistics of setting up events. Their ability to lift heavy loads at height allows equipment to be positioned in elevated areas, such as stages or rigging points, without additional cranes or hoists. This capability reduces setup times and ensures that scheduled events can be completed.

The flexibility of crane pallet forks also makes them useful during event maintenance. Large equipment and props often need to be moved during teardowns or repositioning. Crane pallet forks handle these tasks quickly, ensuring smooth transitions during setup or maintenance periods.

What Does a Pallet Fork Do?

A pallet fork is designed to lift and transport pallets, making the movement of heavy loads much easier and safer. These forks attach to the crane, allowing operators to handle large bulky materials stored on pallets efficiently. The primary function of pallet forks is to lift these loads, making it possible to move them across construction sites, warehouses, and industrial environments.

The design of pallet forks helps maintain balance, ensuring that heavy loads are safely supported during lifting and transportation. This balance is especially important when working with large or uneven loads, as it reduces the risk of tilting, shifting, or dropping items during movement. Proper use of pallet forks helps keep the operator safe and minimizes the chances of accidents or damage to goods.

In addition to their balancing function, pallet forks reduce the need for manual labor. Workers no longer need to manually lift and move heavy pallets, which lowers the risk of injury. Instead, the crane takes on the heavy lifting, allowing employees to focus on other tasks. This contributes to smoother operations and improves overall efficiency.

How to Choose the Right Pallet Forks

Choosing the right pallet forks for a crane can greatly improve efficiency and safety during lifting and transporting materials. Several factors should be considered to ensure the pallet forks meet your operational needs and safety standards.

Weight Capacity

Understanding the weight capacity of the pallet forks is one of the first things to check. Typically, crane pallet forks come with weight capacities ranging from 3,307 lbs to 6,613 lbs, depending on the model. Selecting the right weight capacity is important because using forks with a lower capacity than required can lead to accidents, while oversized forks might be unnecessarily bulky, affecting maneuverability. Always match the weight capacity of the pallet forks to the typical loads you’ll be lifting to ensure optimal performance.

Adjustable vs. Fixed Features

Pallet forks come in adjustable and fixed options. Adjustable pallet forks allow flexibility in load handling, enabling you to adjust the distance between the forks depending on the size of the pallets. Fixed pallet forks are more rigid and are typically designed for specific pallet sizes. Choose adjustable forks if your work involves varying load sizes. Fixed forks, on the other hand, are better for standardized load handling where consistency is key.

Auto-Leveling Technology

One of the most recent advancements in pallet fork design is auto-leveling technology. These forks automatically adjust to maintain a level position while lifting. This reduces the risk of tilting loads, which can cause spills or accidents. If you work in environments where load stability is a concern, auto-leveling crane pallet forks provide added safety and efficiency, minimizing the need for manual adjustments during lifting.

Material and Build Quality

The material and build quality of the pallet forks directly affect their durability and performance. Heavy-duty materials like steel or high-strength alloys are commonly used for crane pallet forks. These materials ensure that the forks can withstand the heavy-duty lifting required in construction, warehousing, and other industrial operations. Additionally, consider the fork’s coating, as certain finishes can help prevent rust and corrosion, extending the life of the forks.

Specific Needs and Industry Requirements

Different industries have unique requirements when it comes to lifting equipment. If your operations involve sensitive materials, you might need pallet forks with specific features like cushioning to protect the load. Heavy-duty pallet forks with higher load capacities are likely necessary for construction and industrial uses. Understanding your specific needs will help you decide on the type of pallet forks that will perform best in your workplace.

Compliance with Safety Standards

Ensuring that your pallet forks meet safety standards is non-negotiable. Many countries and industries have regulations that govern the design and use of lifting equipment. Compliance with standards like those set by ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization) guarantees that the pallet forks are safe to use and built to last. It’s worth confirming that your pallet forks are certified for your region and industry.

What Are Auto-Leveling Pallet Forks?

Auto-leveling pallet forks represent an advanced solution for lifting and transporting loads easily and precisely. This technology automatically adjusts the angle of the forks to keep them level, even when lifting uneven or unstable loads. This innovation helps maintain balance during operation, reducing the risk of tilting or spilling the load, which is crucial in high-stakes environments like construction and warehousing.

The self-leveling mechanism is integrated into the design of the pallet forks, using hydraulic or mechanical systems to keep the forks balanced regardless of changes in load weight or position. This improves safety and enhances operational efficiency by reducing the need for manual adjustments, which can slow down work.

At Bigfoot Crane Company, we excel in providing self-leveling crane pallet forks that are expertly crafted to meet the highest industry standards. These advanced pallet forks for crane combine technology, durability, and safety, offering a reliable solution for any lifting task.

Why Choose Bigfoot Crane Company?

At Bigfoot Crane Company, we offer high-quality crane pallet forks and lifting solutions tailored to our customers’ specific needs.

Commitment to Safety, Durability, and Performance

Our crane pallet forks are designed to endure the tough demands of lifting operations. Using the finest materials, we ensure that each product offers long-lasting durability and excellent performance. Reliability is a key factor in every design, as we know that downtime and equipment failure can disrupt work and increase costs. By choosing Bigfoot Crane Company, you’re investing in lifting solutions that keep your operations running smoothly, day after day.

Compliance with ASME Standards

Safety is our top priority. All our products adhere to ASME standards, ensuring they meet the rigorous requirements set by industry authorities. Compliance with these standards guarantees that each product is built to perform safely and efficiently. This helps reduce risks and ensures that all lifting operations are conducted with the highest level of security.

Expertise, Quick Delivery, and Customer Support

We value our customers’ trust, so we offer expert guidance and quick delivery times. Time matters, so we work hard to provide you with crane pallet forks when needed. Our customer support team is always ready to assist, answering questions or offering advice to help ensure smooth operations at every stage.

Trusted Solutions Across North America

Bigfoot Crane Company has earned a reputation for delivering trusted lifting solutions across North America. Our products help keep your operations running efficiently and safely. Whether you’re in construction, warehousing, or any other industry requiring crane lifting, we provide the right equipment and support to ensure successful outcomes.

Conclusion

Crane pallet forks offer unmatched versatility, enhancing efficiency, safety, and productivity across various industries. Whether you need fixed, adjustable, or auto-leveling pallet forks, the right equipment can significantly affect your operations. We encourage you to consider auto-leveling technology, which provides enhanced load balance and reduces manual adjustments, improving both safety and performance.

At Bigfoot Crane Company, we are committed to delivering high-quality, reliable crane pallet forks designed to meet your needs. Contact us today to learn more and find the perfect lifting solutions for your business. We’re here to help!