Concrete construction projects demand precision, efficiency, and reliability and concrete buckets play a pivotal role in achieving these goals by facilitating the placement of concrete in various construction scenarios. This article explores the significance of concrete buckets, the types, applications, benefits, and associated costs. Whether you are a seasoned professional or new to the field, understanding the role of concrete buckets is essential for optimizing your construction processes.

What is a Concrete Bucket?

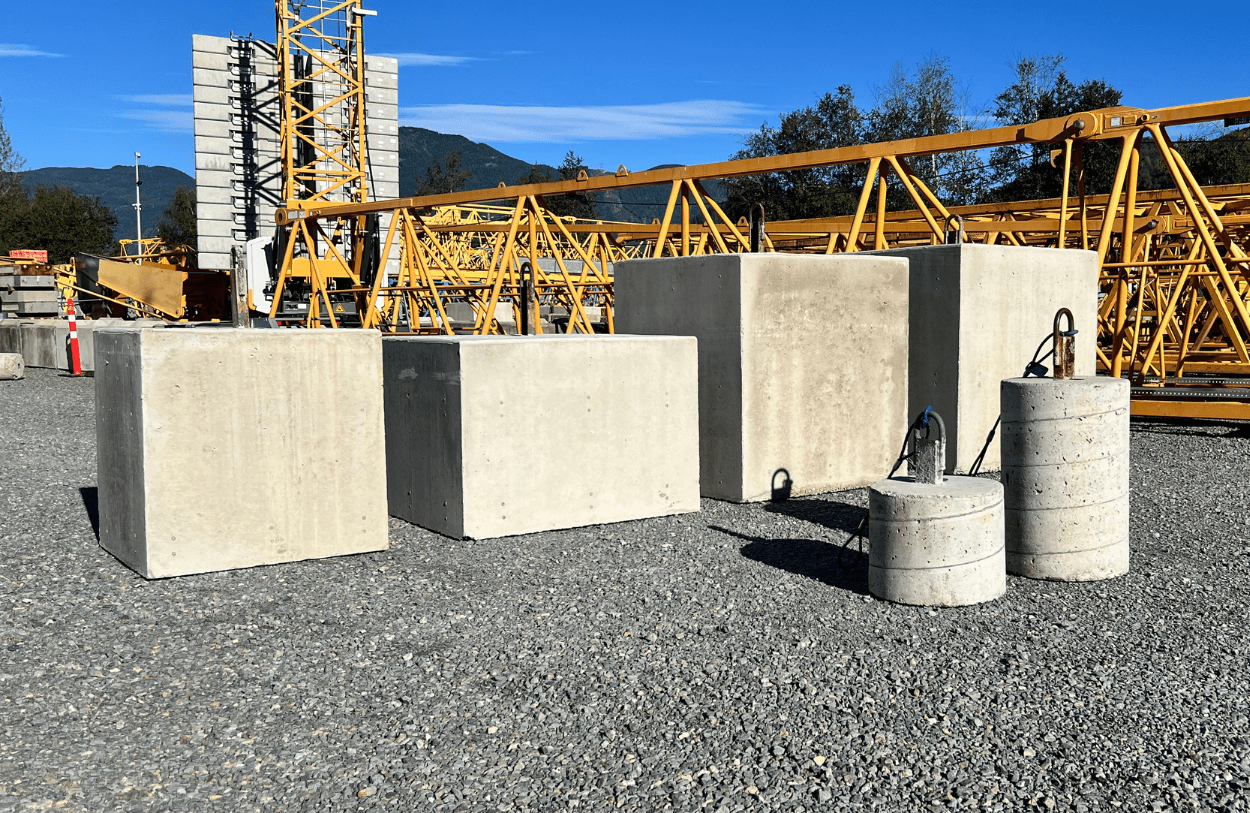

A concrete bucket, also known as a cement bucket or crane bucket, is a container used to transport and pour concrete at construction sites. These buckets are designed to be lifted by cranes or other lifting equipment, enabling the efficient placement of concrete in hard-to-reach areas and ensuring that the mixture is delivered precisely where needed.

Concrete buckets come in various shapes and sizes, including funnel-shaped buckets, dump buckets, and those equipped with chutes for controlled pouring. The choice of bucket depends on the specific requirements of the project, such as the type of concrete being used and the accessibility of the pour site.

Concrete Buckets in Construction

In construction, concrete buckets are indispensable attachments for transporting and placing concrete. They are particularly useful in high-rise buildings, bridges, and other structures where traditional concrete delivery methods may be impractical or inefficient. Concrete buckets enhance the speed and accuracy of concrete placement, reducing the risk of inconsistencies and ensuring a uniform finish.

These buckets are commonly used with cranes, which lift and maneuver them to the desired location. The use of concrete buckets minimizes labor-intensive methods, such as manual pouring, and helps maintain the integrity of the concrete mix by reducing exposure to external elements.

Types of Concrete Buckets

Concrete buckets come in various designs, each tailored to meet specific construction needs. Understanding the different types can help you choose the right tool for your project, ensuring efficiency and precision. Here are some of the most common types of concrete buckets:

Standard Concrete Bucket

The standard concrete bucket is the most basic and widely used type. It is suitable for general concrete placement tasks, making it a versatile choice for many construction projects. Its straightforward design allows for easy handling and maneuvering, ensuring that concrete can be transported and poured efficiently. This type is ideal for standard pours where precision is not the primary concern.

Funnel Bucket

A funnel bucket features a funnel-shaped bottom, which is particularly useful for precise pouring. This design allows the concrete to flow smoothly and accurately into narrow forms or spaces, reducing the risk of spillage and waste. The funnel bucket is ideal for projects that require detailed work, such as filling column forms, foundation walls, and other complex structures. Its ability to control the flow of concrete makes it a favorite for tasks that demand high accuracy.

Concrete Hopper Bucket

The concrete hopper bucket is designed to control the flow of concrete effectively. The hopper mechanism ensures that the concrete is dispensed in a controlled manner, preventing spills and minimizing waste. This type of bucket is perfect for jobs that require consistent and measured pours, such as forming beams, slabs, and footings. Its controlled release feature makes it easier to manage the placement of concrete, enhancing the quality of the final structure.

Self-Dumping Bins

Self dumping bins are designed for quick and easy dumping of concrete. They are particularly useful for large-scale pours where speed and efficiency are needed. The bucket’s design allows for rapid release of its contents, making it suitable for pouring large volumes of concrete in a short period. This type is often used in the construction of foundations, slabs, and other extensive concrete work where time efficiency is essential.

Concrete Bucket with Chute

A concrete bucket with a chute includes a chute for directing the flow of concrete, providing greater control during placement. This design is beneficial for projects that require precise delivery of concrete, such as filling forms with limited access or pouring in tight spaces. The chute allows workers to guide the concrete accurately, ensuring it reaches the intended location without spilling. This type of bucket is ideal for tasks that demand both precision and control, enhancing the overall quality of the concrete placement.

Weight and Capacity of Concrete Buckets

The weight and capacity specification of a concrete bucket vary depending on its size and design. On average, a standard concrete bucket can hold between 0.65 to 3.92 cubic yards of concrete. The weight of an empty bucket ranges from a few hundred to several thousand pounds, depending on its construction and materials.

For example, a typical steel concrete bucket with a 1 cubic yard capacity can weigh approximately 500 to 700 pounds when empty. When filled with concrete, the total weight can exceed 4,000 pounds. Understanding the weight and capacity of the bucket is crucial for safe handling and operation, as well as for selecting the appropriate lifting equipment.

Pricing of Cement and Concrete Buckets

The cost of concrete buckets varies based on their size, design, and manufacturer. On average, a standard concrete bucket can range from $1500 to $42,000. Specialized buckets, such as those with chutes or hoppers, may cost more due to their additional features and complexity.

For instance, a high-capacity concrete bucket with a chute may cost around $43,000 to $105,000. It’s essential to consider the long-term benefits and efficiency gains when evaluating the cost of these buckets, as they can significantly improve the speed and accuracy of concrete placement, leading to overall cost savings in construction projects.

Advantages of Using Concrete Buckets

Concrete buckets offer numerous benefits for construction projects, making them a valuable investment for contractors and builders. Some of the key advantages include:

Efficiency

Concrete buckets play a crucial role in maximizing efficiency when dealing with industrial lifting equipment. They significantly enhance the efficiency of transporting and placing concrete. They streamline the process, allowing concrete to be moved quickly and accurately to the required location unlike when using manual labor. This efficiency reduces labor costs, as fewer workers are needed to manually carry and pour the concrete. Additionally, it shortens project timelines, enabling faster completion of tasks and the ability to take on more projects within a given period.

Precision

One of the standout benefits of concrete buckets is their ability to deliver precise placement of concrete. These buckets are designed to ensure that the concrete mixture is poured exactly where needed, minimizing waste and ensuring a uniform finish. This precision is particularly important in projects that require detailed work, such as filling column forms, foundation walls, and other structures. The controlled pouring capabilities of concrete buckets help achieve consistent and high-quality results.

Versatility

Concrete buckets are available in a variety of designs and capacities, making them highly versatile tools. They can be used for a wide range of construction applications, from small-scale residential projects to large commercial developments. Whether the task involves pouring foundations, columns, walls, or bridge decks, there is a concrete bucket designed to meet the specific needs of the job. This versatility makes them an invaluable asset for any construction project.

Safety

Using concrete buckets enhances safety on construction sites by reducing the need for manual pouring. This minimizes the risk of worker injuries and accidents associated with handling heavy loads and working in hazardous conditions. Concrete buckets allow for safer, mechanized delivery of concrete, promoting a healthier work environment. By improving safety standards, they also help contractors comply with industry regulations and reduce potential liabilities.

Durability

Concrete buckets are made from high-quality materials, such as robust steel, ensuring they can withstand the harsh conditions of construction work. Their durability means they offer long-lasting performance, providing reliable service over many years. Investing in durable concrete buckets reduces the need for frequent replacements, offering cost savings in the long run and ensuring consistent availability of functional equipment for various projects.

Applications of Concrete Buckets

Concrete buckets are versatile tools integral to various construction scenarios, playing a crucial role in delivering and placing concrete with efficiency and precision. Here are some common applications of concrete buckets:

High-Rise Buildings

In high-rise building construction, transporting concrete to upper floors can be challenging. Concrete buckets offer an effective solution by enabling the efficient delivery of concrete to elevated levels. Unlike traditional pumping systems, which can be cumbersome and costly, concrete buckets provide a straightforward method of lifting and pouring concrete directly where it’s needed. This not only speeds up the construction process but also reduces labor costs and the risk of accidents associated with manual handling.

During the construction of skyscrapers, concrete buckets are used to pour concrete for floors, walls, and structural supports. The buckets are lifted by cranes, allowing for precise placement of the concrete, ensuring that the mix is evenly distributed and properly set. This method is particularly useful for ensuring the structural integrity of the building as it rises.

Bridge Construction

Bridge construction requires precise and controlled placement of concrete to ensure the stability and durability of the structure. Concrete buckets are essential in this process, especially for pouring concrete into bridge decks, supports, and piers. The ability to control the flow of concrete with these buckets ensures that the mixture is placed accurately, reducing the likelihood of air pockets and weak spots that could compromise the bridge’s structural integrity.

Concrete buckets are also beneficial in constructing complex bridge elements, such as arches and abutments. Using buckets with chutes or hoppers helps workers direct the concrete flow into tight or intricate forms, achieving a high level of precision and quality in the final product.

Foundations and Footings

The foundation of any building is crucial for its stability and longevity. Concrete buckets are commonly used to pour concrete into foundation forms and footings, providing a solid base for structures. The controlled pouring facilitated by these buckets ensures that the concrete is evenly distributed, preventing voids and ensuring a robust foundation.

In residential and commercial building projects, concrete buckets help in creating concrete floors that support walls and columns. The accuracy of the pour is vital in these applications, as any inconsistencies can lead to structural weaknesses. With concrete buckets, construction teams can achieve a uniform and strong foundation, essential for the overall safety and durability of the building.

Columns and Walls

Concrete columns and walls are essential components of many construction projects, providing support and stability. Concrete buckets allow for the controlled pouring of concrete into column and wall forms, ensuring uniformity and strength. This precision is particularly important in tall structures, where the integrity of columns and walls directly impacts the building’s overall stability.

When constructing parking garages, high-rise buildings, and industrial facilities, concrete buckets are used to fill forms for columns and walls. The buckets enable workers to pour concrete at a consistent rate, reducing the likelihood of air pockets and ensuring that the concrete sets properly. This method contributes to the overall quality and longevity of the structure.

Infrastructure Projects

Large-scale infrastructure projects, such as roads, highways, dams, and tunnels, rely heavily on the efficiency and accuracy of concrete placement. Concrete buckets play a critical role in these developments, enhancing the efficiency and precision of concrete placement.

- Roads and Highways: Concrete buckets are used to pour concrete for road bases, medians, and barriers. The ability to transport and place concrete accurately reduces construction time and improves the durability of the road surface.

- Dams: In dam construction, concrete buckets facilitate the pouring of massive amounts of concrete needed to create the dam structure. The controlled pouring process ensures that the concrete sets correctly, maintaining the dam’s structural integrity.

- Tunnels: Building tunnels requires precise concrete placement to form walls, ceilings, and support structures. Concrete buckets allow for the accurate delivery of concrete in these confined spaces, ensuring the tunnel’s stability and safety.

Concrete buckets also support the construction of other infrastructure elements, such as retaining walls, drainage systems, and culverts. Their versatility and efficiency make them indispensable tools for any large-scale construction project.

Selecting the Right Concrete Bucket

Choosing the right concrete bucket for your project involves considering several factors, including the type of concrete being used, the size and accessibility of the pour site, and the specific requirements of the job. Here are some tips to help you make an informed decision:

- Determine Your Needs: Assess the scope of your project and identify the specific tasks that will require the use of a concrete bucket. Consider the volume of concrete to be poured, the distance it needs to be transported, and any special features that may be required, such as a chute or hopper.

- Evaluate Bucket Capacity: Choose a bucket with the appropriate capacity for your needs. Larger buckets may be more efficient for large-scale pours, while smaller buckets may be more suitable for precise or complex placements.

- Consider Material and Construction: Look for buckets made from durable materials, such as high-quality steel, to ensure long-lasting performance. Consider any additional features, such as reinforced edges or wear-resistant coatings, that may enhance the bucket’s durability and functionality.

- Check Compatibility with Lifting Machinery: Ensure that the bucket is compatible with your lifting equipment, such as cranes or forklifts. Check the bucket’s weight and capacity to make sure it can be safely lifted and maneuvered.

- Compare Prices and Features: Compare different models and manufacturers to find a bucket that offers the best balance of price, quality, and features. Consider the long-term benefits and efficiency gains that the bucket can provide, rather than focusing solely on the initial cost.

Maintenance and Care of Concrete Buckets

Proper maintenance and care of concrete buckets are essential for ensuring their longevity, performance, and safety. Regular upkeep not only extends the life of the equipment but also ensures consistent, high-quality concrete placement. Here are some comprehensive tips for maintaining your concrete buckets:

Regular Cleaning

After each use, it’s crucial to clean the concrete bucket thoroughly. Residual concrete can harden and cause buildup, which can interfere with the bucket’s functionality and reduce its capacity over time. Use water and a stiff brush to remove any remaining concrete. For stubborn residues, a mild acid solution can be effective, but it’s important to rinse the bucket thoroughly afterward to prevent corrosion. Regular cleaning helps maintain the bucket’s smooth interior surface, facilitating better flow and discharge of concrete during future uses.

Inspect for Damage

Regular inspections are vital to identify any signs of wear or damage early. Look for cracks, dents, bent edges, or any signs of metal fatigue. Even small cracks can expand over time and lead to significant structural issues. Addressing these problems promptly can prevent further damage and ensure safe operation. If damage is detected, assess whether it can be repaired or if parts need replacement. Keeping detailed records of inspections can help track wear patterns and predict when maintenance or replacement is needed.

Lubricate Moving Parts

If the concrete bucket has moving parts, such as chutes or hoppers, proper lubrication is essential to maintain smooth operation. Lubricate hinges, joints, and any other moving components regularly to prevent rust and corrosion. Use a high-quality industrial lubricant suited for the bucket’s specific materials and operating conditions. Regular lubrication not only enhances the functionality of the moving parts but also extends their lifespan by reducing friction and wear.

Store Properly

Proper storage of concrete buckets when not in use is crucial to protect them from the elements and prevent rust or corrosion. Store the buckets in a dry, covered area to shield them from rain, snow, and direct sunlight. If indoor storage is not available, use tarps or covers to protect the buckets. Ensure that the storage area is free from excessive moisture and is well-ventilated. Proper storage practices help maintain the structural integrity and appearance of the buckets, readying them for use whenever needed.

Follow Manufacturer Guidelines

Each concrete bucket comes with specific maintenance and care guidelines provided by the manufacturer. Adhering to these guidelines is essential for optimal performance and longevity. The supplier recommendations are tailored to the design and materials of the bucket, providing the best practices for maintenance, cleaning, and storage. Regularly review the manual and ensure that all users are familiar with the care instructions. This can prevent avoidable damage and ensure that the bucket performs reliably throughout its service life.

Additional Tips for Enhanced Maintenance

Use Protective Coatings

Applying protective coatings to the interior and exterior surfaces of the bucket can significantly reduce wear and corrosion. Epoxy coatings or specialized concrete release agents can create a barrier that protects the metal from harsh concrete mixtures and environmental factors.

Implement a Maintenance Schedule

Establishing a regular maintenance schedule can help ensure that all necessary tasks are performed consistently. This schedule should include routine cleaning, lubrication, inspections, and any specific tasks recommended by the manufacturer. Regular maintenance checks can catch issues early, preventing costly repairs or replacements.

Train Operators

Proper training for operators on the correct use and maintenance of concrete buckets is crucial. Ensure that all personnel understand how to handle the buckets safely, perform basic maintenance tasks, and recognize signs of wear or damage. Well-trained operators can significantly extend the lifespan of the equipment through careful use and timely reporting of any issues.

Document Maintenance Activities

Keeping detailed records of all maintenance activities can help track the condition of the buckets over time. Documenting cleaning routines, inspections, repairs, and any issues encountered provides valuable data that can inform future maintenance strategies and budget planning for replacements or upgrades.

Conclusion

Concrete buckets are essential tools for efficient and precise concrete placement in construction projects. By understanding the different types of buckets, their applications, and the benefits they offer, you can make informed decisions that enhance the efficiency and quality of your construction work.

Investing in high-quality concrete buckets and maintaining them properly ensures reliable performance and long-term value. Whether you are working on high-rise buildings, bridges, or infrastructure projects, concrete buckets streamline the process of transporting and placing concrete, contributing to the success and safety of your construction endeavors.