According to the American Society of Mechanical Engineering (ASME), a below-the-hook lifting device is “a tool used to connect a load to a hoist.”. The below-the-hook lifting device is used to help lift and move heavy objects with a crane, hoist, or similar machine. These devices are designed to safely attach to or hold onto the load being lifted, so it doesn’t fall or get damaged.

At Bigfoot Crane Company, we have over 10 years in operation and over 500 projects completed. Our mission is to provide value and build trust in every product and service we provide to our clients. Our customers trust us for all crane and hoist accessories, including below-the-hook (BTH) lifting devices. We are uniquely qualified to provide expert guidance on choosing the right BTH lifting device for your operation.

In this guide, we’ll help you understand the basics of below-the-hook lifting devices, including:

- What is a below-the-hook lifting device, and why is it important?

- What are the different types of below-the-hook lifting devices?

- How to choose the right below-the-hook lifting device for your operation?

- What are the key components of a proper below-hook lifting device?

- What are the proper inspections and maintenance of below-the-hook lifting devices?

- What are the industry standards and regulations for below-the-hook lifting devices?

That said, we hope this guide will educate you and help you choose the right below-the-hook lifting device.

What is a Below-the-Hook Lifting Device and Why is it Important?

Below-the-hook lifting devices help attach a load to a hoist and safely move it from one place to another. It’s also called a BTH device and is an important tool for many production and construction tasks. They include lifting accessories like slings and hooks to hold the load securely. Often these devices are mechanical. But some can also work using electricity, air pressure, or hydraulics.

Custom-built, below-the-hook lifting devices are also common and popular. They are designed for specific loads based on their size, shape, or gravity point. Manufacturers often work with customers to create new devices or adjust existing designs to meet their lifting needs.

In construction, below-the-hook lifting devices are commonly used for tasks such as:

- Lifting Steel Beams: Moving and positioning structural steel for buildings and bridges.

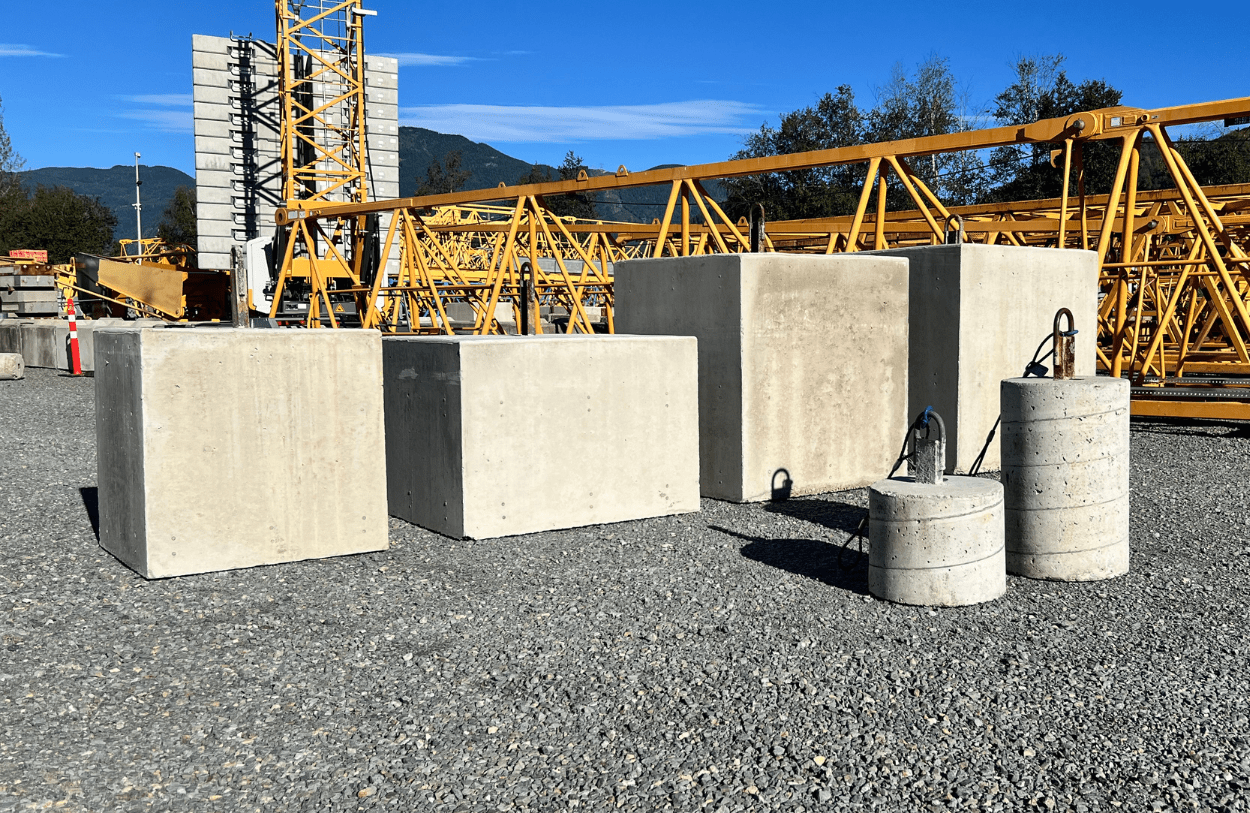

- Handling Concrete Materials: Hoisting large concrete slabs, blocks, or precast components into place.

- Transporting Pipes: Safely lifting and placing heavy pipes for plumbing or industrial systems.

- Moving Machinery: Installing or relocating heavy construction equipment and tools.

- Glass Panel Installation: Lifting and placing large glass panels for windows or facades.

- Roof Trusses and Frames: Hoisting roof trusses or large framework sections into position.

These devices make it safer and easier to lift and move heavy or awkward objects on construction sites.

Types of Below-the-Hook Lifting Devices

There’s a wide array of BTH devices available to suit different industry needs. Some common types include:

- Self Dumping Bins: Automatically tilt to empty contents.

- Pallet Forks: Lift and move pallets with forklifts or telehandlers.

- Outrigger Pads: Stabilize equipment and evenly distribute weight across various surfaces and terrain..

- Hydraulic Pads: Provide support and adjust equipment for stability.

- Material Cages: Safely lift and transport materials in enclosed cages.

- Clamshell Buckets: Transport and evenly distribute loose materials like gravel.

- Crane Man Baskets: Lift workers safely to elevated areas.

- Propane Bottle Carriers: Safely move and lift propane tanks.

- Mortar Buckets: Mix and lift mortar to elevated work areas.

- Concrete Buckets: Lift and pour concrete with precision.

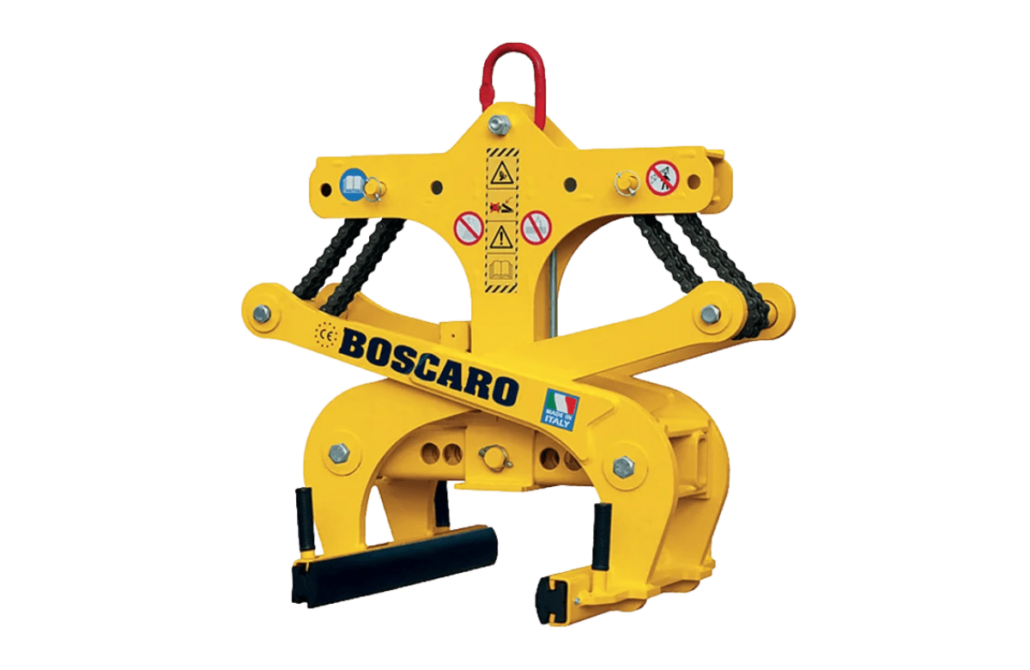

- Jersey Barrier Grabbers: Lift and move concrete barriers securely.

- Lifting Beams: Horizontal bars that evenly distribute the weight of the load.

- Spreader Bars: Designed to spread the load over multiple points.

- C-Hooks: Shaped like a “C,” used for lifting rolls, coils, or similar items.

- Clamps and Grabs: Securely grip the edges of materials like steel plates or beams.

- Magnets: Use magnetic force to lift metal objects without hooks or slings.

- Vacuum Lifters: Use suction to hold flat or smooth materials like glass or panels.

- Slings: Flexible straps or chains that wrap around the load to lift it.

- Tongs: Mechanically grip and lift specific objects, such as logs or pipes.

Each below-the-hook lifting device is designed for specific jobs. It makes lifting safer and more efficient. At Bigfoot Crane Company, we offer a wide selection of underhook accessories for sale and rental. From self-dumping bins to barrier grabbers, we have everything you need for your lifting operation.

Read More: Maximizing Safety and Efficiency with Under Hook Accessories

Importance in Safety and Efficiency

The whole point of using BTH devices is to improve safety and efficiency at work. They reduce the risk of accidents and injuries on the site. BTH devices also increase productivity through faster and more precise load handling.

Below the hook devices also minimize damage to valuable materials and equipment. Moreover, they follow industry safety standards and regulations for overhead lifting operations.

The whole point of using BTH devices is to improve safety and efficiency at work. They reduce the risk of accidents and injuries on the site. BTH devices also increase productivity through faster and more precise load handling.

Below the hook devices also minimize damage to valuable materials and equipment. Moreover, they follow industry safety standards and regulations for overhead lifting operations.

What are the Different Types of Below-the-Hook Lifting Devices?

Below-the-hook lifting devices are crucial tools in material handling. These devices come in various forms, each tailored to specific lifting needs. Let’s explore some of the most common types you might encounter.

Structural and Mechanical Lifters

Structural and mechanical lifting devices form the backbone of below-the-hook equipment. This category includes:

- Self Dumping Bins: Containers designed to automatically tilt and empty contents when lifted.

- Jersey Barrier Grabbers: Attachments for securely lifting and moving concrete barriers.

- EZ Spreader Bars: Bars that distribute loads evenly during lifting operations.

- Lifting Beams and Spreader Bars: These distribute weight across multiple lifting points. They are ideal for long or awkwardly shaped loads.

- Double-beam lifting beams: Used for evenly spreading the load.

- Adjustable lifting beams: Allow for flexibility in load handling.

- Coil Hooks and Lifters: Designed specifically for handling metal coils vertically or horizontally.

- Vertical coil lifters: Feature gripping mechanisms for vertical coil lifts.

- Horizontal coil lifters: Designed to safely transport coils in a horizontal position.

- Pallet Lifters: Featuring forks to securely lift and transport palletized goods.

- Double-pallet handlers: Able to lift and move two pallets at once.

- Forklift-compatible lifters: Equipped with attachments that fit standard forklifts.

- Grab Lifts: Mechanically grip objects like logs, pipes, or other bulky materials.

- Hydraulic grabs: Powered by hydraulics for heavier loads.

- Manual grabs: Operated by hand for smaller or less frequent lifting tasks.

- Suction Cups: Use suction to lift flat surfaces such as glass or panels.

- Heavy-duty suction lifters: Used for large glass panels.

- Pneumatic suction cups: Employ air pressure to lift materials.

- Cable Slings: Steel cables used to securely lift heavy loads. They often use adjustable hooks.

- Single-leg cable slings: Used for lifting single items.

- Multi-leg cable slings: Ideal for stabilizing heavier, larger loads.

- Chain Hoists: Equipped with chains for lifting heavy loads vertically.

- Manual chain hoists: Operated by hand.

- Electric chain hoists: Powered by electricity for heavier loads.

- Beam Trolleys: Move lifting beams along a track to cover a wider area for lifting.

- Push beam trolleys: Manually moved by workers.

- Motorized beam trolleys: Electrically powered for easy positioning.

- Safety Latches: Devices that ensure loads stay securely attached during lifting.

- Spring-loaded latches: Automatically secure the load.

- Manual safety latches: Require manual engagement for added security.

Specialized Gripping Devices

For loads requiring a more specialized approach, there are several options:

- Vacuum Lifters: Uses suction to grip and lift non-porous materials. Ideal for materials like glass or metal sheets.

- Portable vacuum lifters: Lightweight and easy to transport.

- Stationary vacuum lifters: Used for repetitive lifting tasks.

- Rotating vacuum lifters: Equipped with rotating heads for precise positioning.

- Magnetic Lifters: Ideal for ferrous materials. These can be either electrically powered or permanent magnets.

- Electromagnetic lifters: Electrically powered for stronger holding.

- Permanent magnetic lifters: Use magnetic fields without power.

- Lifting magnets with adjustable force: Allow control over the magnetic grip.

- Plate Clamps and Sheet Lifters: These grip the edges of flat materials for secure lifting.

- Mechanical plate clamps: Secure flat plates with ease.

- Pneumatic sheet lifters: Grip sheet materials with air pressure.

- High-strength plate clamps: Designed for heavy-duty lifting of thick metal sheets.

Versatile Handling Equipment

Some below-the-hook lifting devices are designed for specific industries or applications:

- Pallet Forks: Attachments used for lifting and moving palletized loads with forklifts or telehandlers.

- Outrigger Pads: Durable mats placed under outriggers to stabilize equipment and distribute weight.

- Material Cages: Enclosed cages used to securely lift and transport materials.

- Clamshell Buckets: Hinged buckets ideal for transporting loose materials like gravel or sand.

- Drum Handlers: Specialized for safely lifting and maneuvering industrial drums.

- Tilt drum lifters: Allow for safe tilting and emptying.

- Fork-mounted drum handlers: Attach to forklifts for easy drum handling.

- Rotating drum handlers: Equipped with mechanisms to rotate drums for easier access.

- Man Baskets: Designed for lifting personnel to elevated work areas safely.

- Crane man baskets: Lift workers safely to elevated areas.

- Fall protection baskets: Equipped with safety harness points.

- Compact man baskets: Lightweight and easy to maneuver.

- Extended man baskets: Allow for more space and tools during elevated tasks.

- Scrap and Material-Handling Grapples: Used in recycling and bulk material handling.

- Hydraulic grapples: For heavy-duty scrap handling.

- Hydraulic accessories: Provide support and adjust equipment for stability.

- Manual scrap grapples: Used for smaller loads.

- Rotating scrap grapples: Allow for precise control of material placement.

- Multi-Purpose Lifting Devices: Versatile tools used in various industries for different tasks.

- Lifting magnets with vacuum: Combine magnetic force and suction for unique applications.

- Adjustable beam attachments: Fit multiple lifting devices onto the same beam for flexible use.

- Multi-function grabs: Designed to handle both long and bulky items as well as small parts.

- Propane Bottle Carriers: Secure carriers for transporting and lifting propane tanks safely.

- Mortar Buckets: Sturdy buckets used for mixing and lifting mortar to elevated work areas.

- Concrete Buckets: Specialized containers designed for lifting and pouring concrete.

When choosing below-the-hook lifting devices, consider the load’s weight and shape. Take into account the material and lifting environment. Ensure the device complies with CSA-approved safety standards for design and operation. The right device enhances material handling efficiency and promotes workplace safety.

How to Choose the Right Below-Hook Lifting Device for Your Application

Selecting the right below-the-hook lifting device is important. It helps ensure safety, efficiency, and compliance in your material handling operations. Here’s how to make the right choice:

Assess Your Load Characteristics

Begin by thoroughly evaluating the loads you’ll be lifting. Consider factors such as:

- Weight and dimensions

- Shape and center of gravity

- Material composition

- Environmental conditions (temperature, humidity, corrosive elements)

Understanding load characteristics is crucial. It helps in matching them with the right below-the-hook lifting devices.

Determine Your Lifting Requirements

Next, analyze your specific lifting needs:

- Required lifting capacity and safety factor

- Lift height and reach requirements

- Frequency of use and duty cycle

- Attachment points on the load

Remember, below hook lifting devices are often custom-engineered to meet unique application demands.

Consider Safety and Compliance

Focus on safety by selecting equipment that adheres to industry standards:

- Ensure compliance with CSA, OSHA, and ASME guidelines.

- Verify the equipment meets the necessary CSA certifications and OSHA safety requirements.

- Check for relevant safety features and additional certifications to ensure optimal protection and adherence to regulations.

Consult with Experts

At Bigfoot Crane Company, we offer consulting to help you choose the right below-the-hook lifting devices. We make sure you understand the best equipment for your needs. We also ensure safe and efficient lifting in your operations.

What are the Key Components of a Proper Below-Hook Lifting Device?

A below-the-hook lifting device is used to attach heavy loads to a crane, making it easier to move them safely. Let’s take a closer look at some common parts and how they help the device work.

- Bail. This is where the crane hook connects to the lifting device. Bails can be plate-style (flat) or pin-style (with a hole).

- Lifting Lug. This is the part where you connect rigging equipment like a shackle or hook to lift the load.

- Gusset. This is a strong plate welded onto the device in areas where there is a lot of stress. It helps make the device stronger.

- Latch. A device that holds the hook open or closed, it makes sure the load stays safely attached during lifting.

Important Considerations

Under-the-hook lifting devices must adhere to strict CSA-approved safety standards. These products are designed to meet high safety factors, ensuring reliable performance under varying conditions. The most common design classification aligns with rigorous safety requirements for unpredictable loads or severe conditions. Lifters are rated by service class based on load cycles, with Class 2 (100,001 to 500,000 cycles) being widely used.

The materials and welds in these devices meet CSA-approved strength and safety standards. All welding is performed following certified procedures to ensure quality and compliance.

For below-the-hook lifting devices weighing over 100 lbs, proper labeling is essential. A tag must include:

- Working load limit

- Design criteria

- Manufacturer information

- Electrical specifications (if powered)

The device should include detailed documentation, like design calculations and test results. This will prove that the product meets safety standards. This also helps ensure proper use and maintenance.

What are the Proper Inspection and Maintenance of Below-the-Hook Lifting Devices?

Proper inspection and maintenance of below-the-hook lifting devices are crucial. It ensures workplace safety and OSHA compliance. These devices require regular attention to function safely and effectively.

Inspection Types and Frequency

According to ASME B30.20 standards, there are three main types of inspections for below-the-hook lifting devices:

- Pre-use inspection. Operators must visually inspect the device before each use, checking for any visible damage or wear.

- Frequent inspections. Depending on service conditions, these should be conducted monthly to daily by the operator.

- Periodic inspections. A qualified person should perform these inspections yearly to quarterly, maintaining written records.

Key Maintenance Do’s

- Always read and follow the manufacturer’s instructions for each lifting device. Verify equipment adjustments, rigging methods, and load capacity before each use.

- Ensure all operators are properly trained on the safe use and operation of the equipment.

- Devices in harsh conditions or with heavy use may need more frequent inspections and maintenance.

Important Don’ts

- Never use damaged or malfunctioning below-the-hook lifting devices.

- Avoid shock loading, dragging, or pushing the device.

- Do not lift, lower, rotate, or transport personnel with the equipment.

- Never exceed the rated capacity of the device or the hoist/crane.

By following these guidelines, you can ensure the longevity and safe operation of your below-the-hook lifting devices. Following them also helps maintain compliance with OSHA regulations and industry standards.

How to Ensure Safety When Using Below the Hook Lifting Devices?

Understand the Basics

When working with below-the-hook lifting devices, safety should always be your top priority. These tools are designed to securely attach loads to overhead cranes or hoists. To ensure safe operations, it’s essential to familiarize yourself with industry standards. These are the ASME B30.20 and ASME BTH-1, which outline design, manufacture, and usage requirements for below-hook lifting devices.

Put in place Proper Training and Inspections

All operators must receive thorough training on the safe use of below-the-hook lifting devices. This includes understanding the equipment’s capacity, proper attachment methods, and potential hazards. Regular inspections are crucial:

- Conduct visual checks before each use.

- Perform frequent inspections (daily, weekly, or monthly).

- Schedule periodic inspections (quarterly, semi-annually, or annually).

Always maintain detailed records of these inspections. It helps ensure compliance and track the device’s condition over time.

Follow Best Practices

Follow these key practices to ensure safety with below-the-hook lifting devices.

- Verify that the load doesn’t exceed the device’s rated capacity.

- Ensure proper balance and full engagement of the load.

- Move loads smoothly, avoiding sudden accelerations or decelerations.

- Never use damaged or malfunctioning equipment.

- Keep personnel clear of swing zones, fall zones, and crush zones.

Industry Standards and Regulations for Below-the-Hook Lifting Devices

Key Standards and Guidelines

It’s important to understand the industry standards that govern the design, manufacture, and use of these devices. The two primary standards are ASME B30.20 and ASME BTH-1, which define the requirements for these critical pieces of equipment. These standards make sure lifting devices meet strict safety and performance requirements.

Design Categories and Service Classes

Below-the-hook lifting devices are classified into different design categories and service classes. According to ASME BTH-1, there are two design categories:

- Category A: For predictable loads and defined environmental conditions

- Category B: For unpredictable loads and severe or undefined conditions

Additionally, five service classes (0-4) are defined based on the expected load cycles in a 24-hour period. It’s important to understand these classifications to choose the right lifting device for your needs.

Compliance and Safety Requirements

To ensure OSHA compliance and workplace safety, the devices must meet key requirements.

- Clear marking of the rated load on the device or an attached tag

- A nameplate displaying manufacturer information, serial number, and ASME classifications

- Proper safety labels warning against unsafe practices

- Regular inspections, including before/during use, frequent, and periodic checks

- Welding performed under ANSI/AWS D14.1 and ASME BTH-1 standards

Frequently Asked Questions About Below The Hook Lifting Devices

What are below-the-hook lifting devices?

Below-the-hook lifting devices are tools that help control and support loads during lifting. These devices are specially designed for more precision and safety than traditional rigging.

How do I choose the right under-the-hook lifting device?

When selecting below-the-hook lifting devices, consider the following factors:

- Load capacity and dimensions

- Environmental conditions (heat, chemicals, obstructions)

- Current lifting method and desired improvements

- Crane hook size and compatibility

- Budget and delivery timeline

Providing detailed information about your specific needs, including engineering drawings or 3D models, can help manufacturers design a more accurate solution for your application.

What standards govern below-the-hook lifting devices?

Two primary standards govern the design and use of below-the-hook lifting devices:

- ASME B30.20: Defines general requirements for design, marking, and compliance

- ASME BTH-1: Specifies design categories and service classes

These standards ensure that lifting devices meet safety and performance requirements.

What is the below-the-hook design category?

Below-the-hook design category B applies to lifting devices when the load magnitude and conditions are unpredictable, and where loading and environmental factors are severe or not clearly defined. This category ensures that the device is built to handle challenging and uncertain lifting situations.

What is the minimum safety factor for a below-the-hook lift device?

The minimum safety factor for a below-the-hook lifting device typically depends on the load and the environment where it will be used. Design Category B, the most common classification, requires a minimum safety factor of 3:1 to ensure durability and reliability under challenging and uncertain conditions.

Do lifting devices need to be certified?

Lifting devices must meet strict certification and testing requirements to ensure safety and compliance. According to OSHA regulations, any custom-designed grabs, hooks, clamps, or other lifting accessories must be proof-tested before use. This ensures they can handle the load safely and reduces the risk of equipment failure. Failure to adhere to these standards not only compromises workplace safety but also violates OSHA regulations, leading to potential fines and penalties.

Conclusion

Choosing the right below-the-hook lifting device can make a significant difference in ensuring safe and efficient operations. At Bigfoot Crane Company, with over 10 years of experience and successfully completed projects, we are dedicated to providing reliable solutions tailored to your specific needs. Our mission is to offer value and build trust with every product and service we deliver.

In this guide, we’ve covered the basics of below-the-hook lifting devices. We hope this guide helps educate you and assists in making an informed decision. If you need further guidance or want to explore your options, feel free to reach out to us at 1-877-852-2192 / (604) 854-3218 or contact us for expert advice. We’ll assign a specialist who can provide personalized support and help you find the best solution for your lifting needs.