Crane material baskets provide an effective method for moving heavy materials around construction and industrial sites. Also referred to as material cages, these lifting platforms allow the safe transport of oversized loads that are difficult to manage with conventional equipment. They operate in conjunction with cranes to enhance the efficiency and safety of material handling. Crane material baskets are built to withstand harsh conditions, ensuring secure and dependable transport of materials. Being knowledgeable about the different types and safety mechanisms of crane material baskets greatly enhances their application, thus improving workflow and safety on any worksite.

What Is A Crane Material Basket?

Material baskets are a type of transport equipment that combines a frame and a platform for transporting various construction materials at an industrial site. Sturdily built to endure harsh conditions and heavy lifting, these baskets are attached to cranes for safe and easy lifting and movement of large and heavy construction materials.

Material Baskets for Cranes

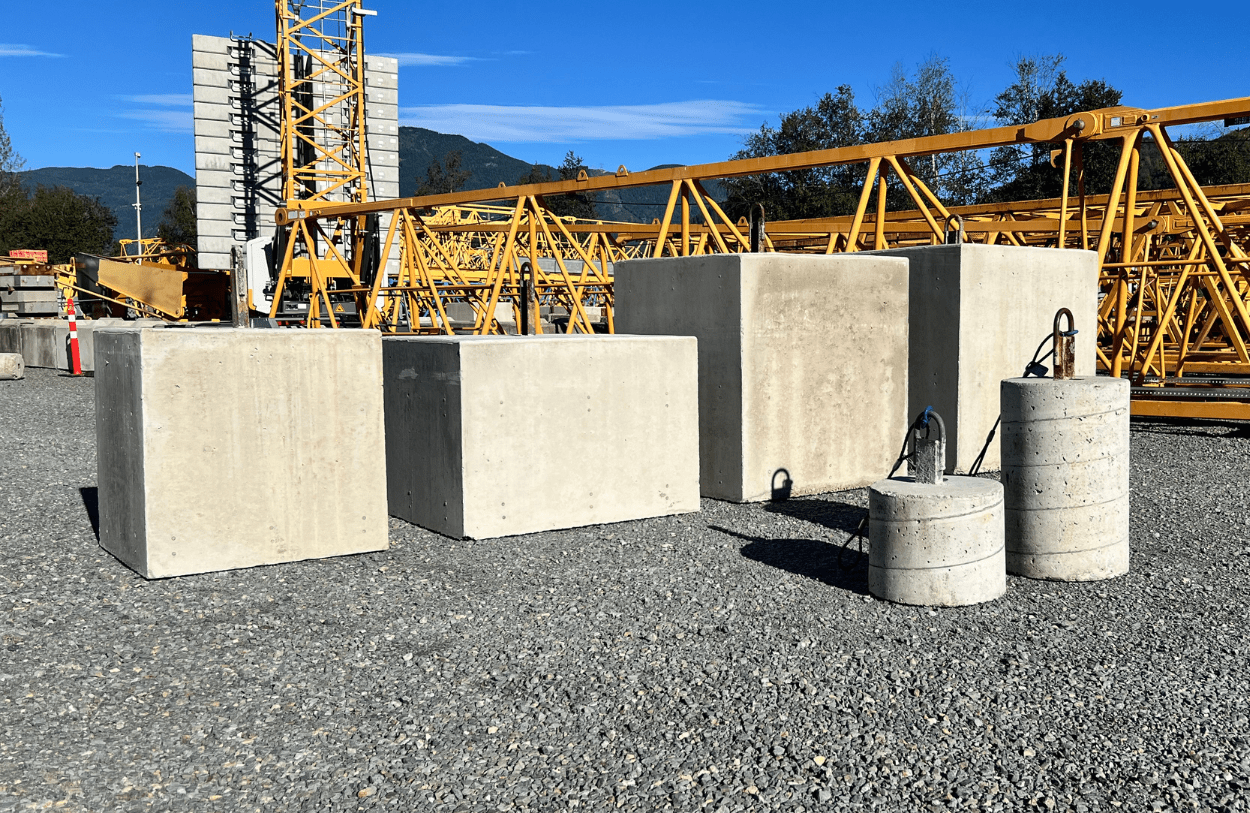

Industrial and construction processes require material baskets for cranes. These baskets assist lift and transfer of items safely and conveniently. When fitted with cranes, they offer a safe means of transporting large and cumbersome items that are difficult to move manually or with regular tools. Crane material baskets are made of durable materials like steel to withstand tough working environments, often prevalent at job sites.

One of the primary benefits is that crane material baskets serve various functions that pertain to their versatility. They are made in different volumes, which allows them to transport a wide variety of loads. These baskets are designed to withstand all of it, from heavy construction materials to light machinery.

Loading and unloading materials is also simple. Workers can place materials into the basket with ease and ensure safety during the operation. These factors assist in boosting the pace at which projects are completed while also decreasing spending on labor.

The Different Types of Crane Material Baskets

Crane material baskets come in several types, each suited for different lifting and transport tasks. Here’s an overview of the most common types:

Goods Carrying Cages

Goods carrying cages are ideal for general material handling. They feature enclosed sides and durable mesh or paneling to securely contain loose items, packaged goods, or bulky materials during lifting and transport.

Stacking Bins

Stacking bins offer a space-saving solution when working with limited ground area. They’re designed to nest or stack securely, allowing teams to organize materials vertically without compromising safety or access. These bins are especially useful in industrial environments and warehouses.

Brick Handling Cage

Brick handling cages are reinforced to carry dense, heavy materials like bricks or pavers. They provide stable support and secure containment, helping crews transport masonry supplies without shifting loads or risking damage to the structure or contents.

Material Handling Bin

Material handling bins are versatile, open-top containers used for transporting heavier bulk materials like concrete debris, scrap, or equipment. Their rugged build and open design make loading and unloading fast and efficient.

Material Platforms for Forklifts & Cranes

Construction and warehouse activities in different sectors require lifting and transporting materials. These processes are made simple by the use of material platforms, which are an essential tool. They are designed to be used with forklifts and cranes so they can be moved effortlessly from one position to another when the heavy load is located in tight spaces. Customization of the platform is possible depending on the material being lifted, which could be construction tools, raw materials, or even sensitive equipment that needs a gentle hand. For a wide range of projects, material platforms are available in various sizes and shapes to meet the requirements.

Enhanced efficiency comes from using forklifts and cranes with material handling cages and platforms that often feature fork pockets. These fork pockets allow forklifts to easily engage and transport large or heavy items over distances, expanding their lifting capabilities. In construction settings, cranes can lift these cages and platforms several floors, which is especially important for oversized or unusually shaped materials. The sturdy design of the cages and platforms helps maintain stability and security during lifting, reducing the risk of accidents and minimizing material damage.

High-Quality, Dependable Material Cages

Material cages assist in the underpinning structure of the material platform system. They are additionally important for providing more safety and protection to the materials being lifted. Robust items such as steel are used in constructing material cages which serve to protect the load and prevent falling or shifting of items during transport. Depending on the job requirements, these cages can be used with either cranes or forklifts.

High-quality material cages are designed to withstand extreme conditions, including heavy weights, harsh weather, and continuous use. Dependable cages feature reinforced frames, secure locking mechanisms, and sometimes mesh sides for visibility, ensuring that everything inside stays securely in place. This added security helps keep workers safe and minimizes the chances of accidents. Whether for industrial, commercial, or construction applications, material cages are indispensable tools for improving the safety and efficiency of lifting operations.

How to Lift a Crane Material Basket

Both personnel and materials involved require utmost safety and care while lifting a crane material basket, making planning and technique crucial. Evaluating the load is the first step, followed by confirming the basket is secured. This also means checking that all locking mechanisms are operational and the load is properly balanced within the basket. Always ensure the basket is not overloaded beyond its specified capacity, as this can lead to instability issues during the crane lift.

Once the basket is prepared, position the crane’s hook directly above the center of the basket. Ensure that the lifting cables or chains are securely attached to the basket’s designated lifting points. It’s important to double-check the integrity of the lifting slings to avoid any accidents. Slowly begin lifting the basket, maintaining a steady and controlled motion. Keep a close eye on the load, making sure it doesn’t shift or sway excessively.

Communication between the crane operator and the ground crew is crucial during the lift. Using clear and concise signals, the ground crew can guide the operator, ensuring the load is raised smoothly and without incident. Once the basket is lifted off the ground, ensure it is elevated to a safe height before transporting it to its destination.

Lifting Technologies Material Baskets

Lifting Technologies’ material baskets are specially designed to offer maximum safety and optimization during heavy lifting operations. Made from robust, constructed material, these baskets provide an exceptional safeguard for the load alongside the crane operator. The design incorporates numerous safety features such as reinforced lifting points and secure locking systems to guarantee the safe transport of all materials.

Additionally, the baskets are equipped for use on nearly all types of cranes. This endless adaptability allows usage across many industries. Whether lifting construction materials, equipment, or any other heavy load, Operations are smooth and secured on every job with Lifting Technologies’ material baskets every single time. Its thoughtful design allows easy handling while increasing worker safety.

Safely Transporting the Cage

Safely transporting a cage requires attention to several key factors. Follow these steps to ensure the process goes smoothly:

- Secure the Load: Before transport, make sure that the load within the cage is both stable and secure. Adequate restraint must be done to prevent movement within the cage.

- Check Lifting Attachments: Make sure all lifting slings or chains have been attached to the correct designated lift points on the cage.

- Slow and Steady Lift: Crane movements should be slow and controlled to minimize the risks of jerky or sudden movements that may threaten stability.

- Coordinate Communication: Ensure that communication between the crane operator and the ground crew is maintained throughout the operation. Each member should manage their section and handle it with precision.

- Monitor Stability: Always check the cage for balance during the entire transport, maintaining stability throughout at all times. Stability monitoring is critical.

The Benefits of Crane Material Baskets

Load Tested

Crane material baskets undergo precise load testing to guarantee safety compliance. These tests determine the overspill and maximum amounts each basket can hold in weight without shifting. The level of reliability your equipment can be trusted with is notably higher when you know that it has undergone such testing, considering a myriad of factors such as the chances of accidents.

Guaranteed Safe

Crane material baskets are load tested and OSHA/CSA approved, ensuring safety every time they are used. Additionally, every basket is certified to carry the marked load, providing assurance while ensuring safe and smooth operations during lifting. These baskets are built to endure severe conditions, offering much-needed peace of mind for operators.

Custom Material Baskets

Custom material baskets are designed to meet the unique needs of your lifting operations. Whether you require specific sizes, shapes, or features, these baskets are tailored to optimize efficiency and safety.

Custom Built

Each custom material basket is built to your exact specifications. Whether you need a basket that fits unusual dimensions or special requirements, a tailored design ensures the basket is perfect for your lifting needs. These custom solutions provide greater flexibility, ensuring the safety and effectiveness of your operations.

Study Design

A well-thought-out design is at the core of every custom material basket. Carefully considering load distribution, stability, and durability ensures that the basket performs reliably under tough conditions. Each design is made to meet your exact requirements, prioritizing safety and efficiency.

Download the Product Brochure

Want more details? Download our product brochures to get full specifications, features, and design options for custom material baskets. It’s a great way to see how we can meet your specific needs.

– CST-D Material Handling Bin Technical Specifications

– BSC Series Brink Handling Cage Technical Specifications

– CPF Mobile Cages Technical Specifications

– CML Series Stacking Bins Technical Specifications

– CMR Series Stacking Bins Technical Specifications

Request a Quote

Looking for a custom material basket? Request a quote today, and let us provide you with an accurate estimate based on your specific needs. We offer tailored solutions to fit your requirements and ensure top-quality performance.

Learn More About Our Material Baskets

Want to know more about our material baskets? Explore our product details, design options, and features to find the perfect solution for your lifting needs.

Conclusion

Every lift should feel reliable. That’s what a well-built material basket offers. Ours are made to handle tough tasks while helping your crew stay efficient and safe. If your job has specific needs, our team can build a basket that fits just right. Reach out to our team today and see how the right basket can make your lifting jobs easier, safer, and more efficient.

FAQs for Material-Only Work Platforms

What Types of Material Cages Can I Buy from Bigfoot Crane Company?

We offer several material-only platforms, including open-style baskets, enclosed cages, and custom-built designs made for specific lifting applications.

Are Any of the Material Platforms Featured in the Photo Gallery in Stock?

Some of the featured platforms may be available. Inventory changes often, so it’s best to contact our team for the latest update.

Do You Stock Any Material Platforms?

We carry a limited number of ready-to-ship platforms. Most are made to order based on your requirements.

Do the Material Platforms Meet OSHA Standards?

Yes. All of our material-only baskets meet applicable OSHA standards for lifting and rigging.

Do You Build Material Platforms to Any Other Standards?

Yes. We can build to CSA, ANSI, or project-specific requirements when needed.

What Are the Capacities of the Material Platforms?

Capacities vary by design but are clearly marked on each platform. We match each build to your load needs.

Are the Dimensions of the Material Platforms I.D. or O.D.?

We list outside dimensions unless stated otherwise. Let us know if you need inside measurements.