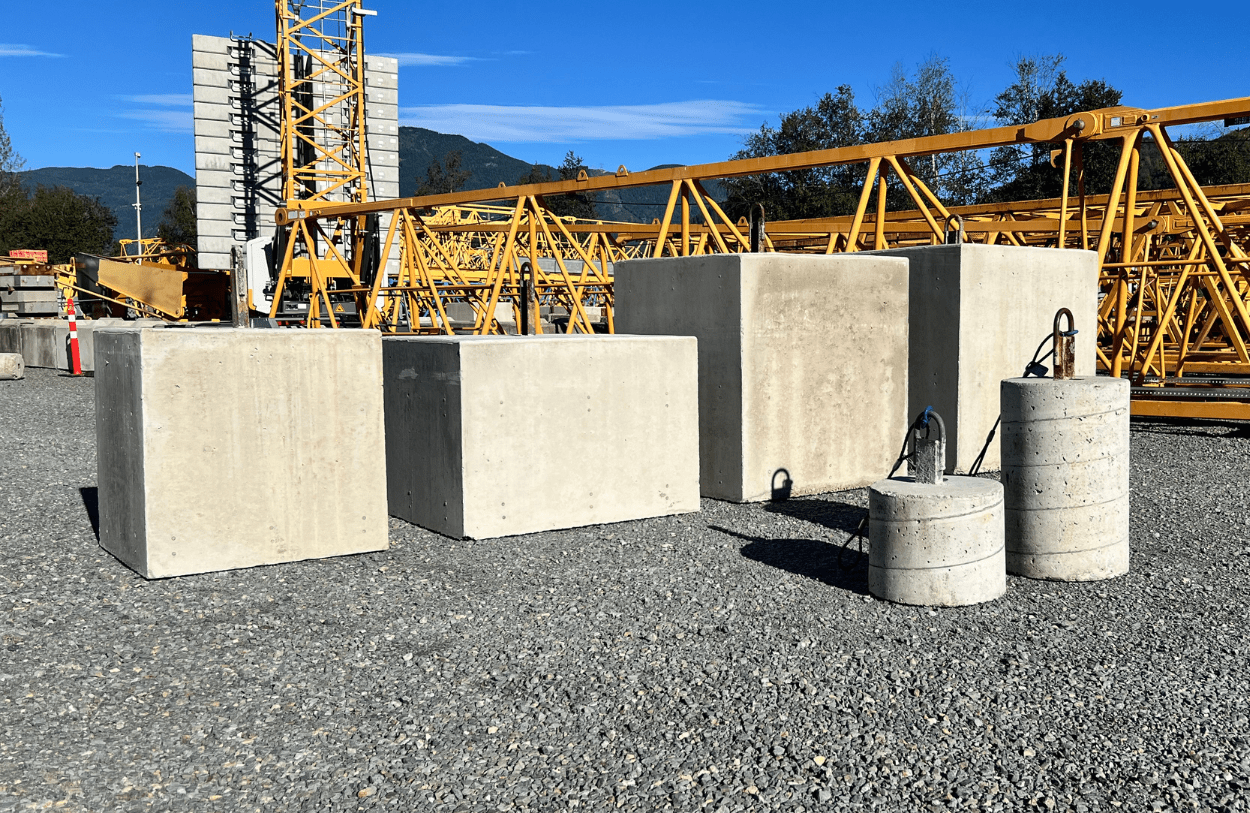

Winter weather poses unique challenges for construction sites, from freezing temperatures and high winds to snow and ice accumulation. To maintain safety and productivity, it’s essential to prepare your site for these harsh conditions. This guide outlines practical steps to protect your construction site during winter.

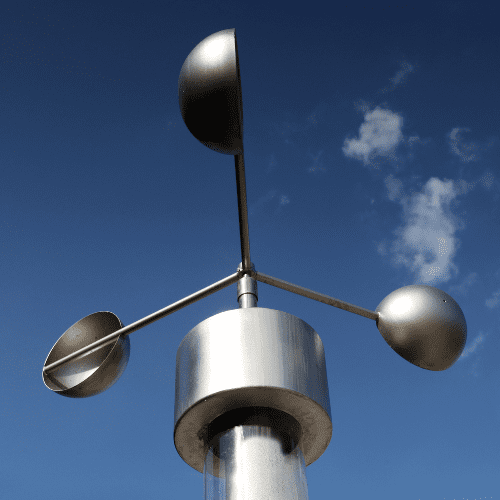

Step 1: Prioritize Wind Monitoring with Anemometers

Wind is one of the most unpredictable and hazardous elements during winter. High winds can destabilize cranes, scatter materials, and create unsafe working conditions. Anemometers, devices that measure wind speed and direction, are crucial for maintaining site safety.

How Anemometers Protect Your Site

- Real-Time Wind Data: Advanced anemometers like the W410XB Wireless Anemometer available at shop.bigfootcrane.com provide real-time wind monitoring, helping you make informed decisions.

- Safety Threshold Alerts: Set wind speed thresholds to determine when crane operations should pause.

- Weather Adaptability: Durable models from Bigfoot Crane Company function effectively even in freezing temperatures, ensuring consistent monitoring.

Where to Install Anemometers

- On Cranes: Attach anemometers directly to tower cranes or mobile cranes for accurate wind readings at operational heights.

- Onsite Monitoring Stations: Use portable or handheld anemometers to monitor wind conditions around key work areas.

Equip your site with reliable anemometers this winter. Shop Anemometers Now and ensure wind safety on your project.

Step 2: Ensure Safe Fuel Transport with Propane Bottle Carriers

Propane is essential for heating equipment, tools, and workspaces in freezing conditions. However, transporting propane safely can be challenging without the right tools. The Boscaro PB-2BF Propane Bottle Carrier is specifically designed to secure and transport propane bottles safely.

Benefits of Propane Bottle Carriers

- Secure Transport: Holds up to two propane bottles (up to 31 inches in diameter) with tie-down points to prevent shifting.

- Versatile Handling: Features fork pockets and crane lifting eyes, allowing easy transport by forklift or crane.

- Durability: Built from 100% welded steel with a powder-coated finish, these carriers withstand tough winter conditions.

- Space Efficiency: Stackable design optimizes storage space when not in use.

Use Cases in Winter

- Heating: Transport propane to keep heaters running and prevent freezing.

- Fueling Equipment: Supply propane to forklifts, generators, and other critical tools.

- Temporary Warm Areas: Move propane efficiently to heat temporary shelters or workspaces.

Keep your team warm and safe this winter by purchasing or renting our Propane Bottle Carriers today!

Step 3: Prepare for Snow and Ice Management

Snow and ice can obstruct access, create slippery surfaces, and damage materials. Effective management strategies are essential to maintain safety.

Key Steps for Snow and Ice Removal

- Clear Work Areas Regularly: Schedule frequent snow removal to prevent accumulation.

- Use Ice-Melting Products: Apply salt or eco-friendly alternatives to reduce ice on walkways and work surfaces.

- Protect Equipment: Cover machinery and materials with tarps to prevent ice damage.

Step 4: Winterize Your Equipment

Cold weather can impact machinery performance, increasing the risk of breakdowns. Take the following steps to prepare your equipment for winter:

- Perform Maintenance Checks: Inspect all machinery for issues like worn parts or low fluid levels.

- Use Winter-Grade Fluids: Replace standard fluids with winter-grade alternatives to ensure smooth operation in freezing temperatures.

- Protect Hydraulic Systems: Keep cranes and hoists functioning optimally by monitoring for hydraulic freezing.

Prepare your tower cranes for harsh winter conditions with legendary servicing from Bigfoot Crane Company. Ensure optimum performance and safety, even in freezing temperatures.

Step 5: Train Your Team for Winter Operations

Even with the best equipment, your team must be prepared to handle winter-specific challenges.

Training Tips

- Wind Safety Protocols: Train staff on using anemometers and responding to wind alerts.

- Cold Weather Preparedness: Teach workers to recognize signs of frostbite and hypothermia.

- Emergency Procedures: Review evacuation plans and emergency response protocols for winter-specific hazards.

Step 6: Create a Winter Safety Plan

A comprehensive safety plan is essential for managing risks during winter construction.

What to Include

- Wind Thresholds: Define wind speed limits for different activities using anemometer data.

- Snow Removal Schedule: Establish a routine for clearing snow and ice.

- Communication Plan: Use radios or mobile devices to ensure consistent communication during adverse weather.

Step 7: Monitor and Adjust Daily

Winter conditions can change rapidly, making daily monitoring essential. Anemometers provide real-time data to adapt your operations as needed.

Daily Checklist

- Check Wind Conditions: Use portable or fixed anemometers to assess wind safety.

- Inspect Equipment: Ensure all machinery is winter-ready and functioning properly.

- Communicate Updates: Inform the team of weather changes and adjustments to operations.

Be prepared for winter challenges with the right tools and equipment. Visit bigfootcrane.com to explore our full range of safety solutions, including anemometers, propane bottle carriers and crane and hoist servicing.

Conclusion

Winter construction doesn’t have to mean downtime or increased risks. With the right preparation, tools, and safety protocols, your site can remain productive and safe even in the harshest conditions.

Investing in anemometers and propane bottle carriers from Bigfoot Crane Company ensures you’re equipped to tackle winter’s challenges head-on. From wind monitoring to fuel transport, these tools help you maintain efficiency while prioritizing safety.

Protect your site this winter. Shop Now for the best winter safety solutions!