Mastering the Craft: Elevate Your Career with Level 1 Rigging Certification

Gain essential skills with Bigfoot Crane Academy’s Level 1 Rigging Certification, blending classroom theory with practical training for a safe, skilled career in rigging.

Your Essential Guide to Overhead Crane Safety

Overhead crane safety is crucial to prevent accidents. Key practices include avoiding overloading, daily inspections, and adhering to safety guidelines.

Enhancing Crane Operations: A Comprehensive Guide to Crane Underhook Accessories for Safety and Efficiency

Explore how underhook accessories enhance crane safety and efficiency. Discover Bigfoot Crane’s robust and advanced lifting solutions.

Becoming Compliant with New Anti-Collision Regulations for Tower Cranes in BC

Bigfoot Crane helps BC companies navigate new WorkSafeBC anti-collision and zoning regulations for tower cranes, offering services like OEM communication, panel inspections, and system installations.

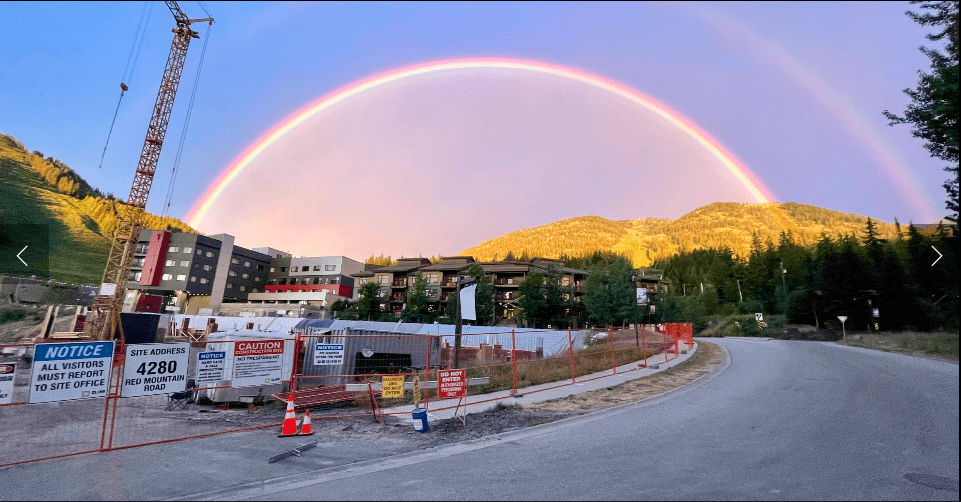

The Rossland Rescue and Bigfoot’s Core Values

“We had a concrete pour scheduled for Friday before the long weekend,” said Justin Tanguay, of DJM Contracting in Rossland, B.C., “but our crane was down.”

Justin and his team were well aware that concrete was in high demand at the time. So, rescheduling a pour could completely mess up project planning. “There was something wrong with the slew motor on our…

Bigfoot Just Got Twin Liebherr 81 K.1 Self Erecting Tower Cranes

We are pleased to announce the addition of two new cranes to our fleet! Bigfoot has just acquired two of Liebherr’s 81 K.1 Fast-Erect self-erecting tower cranes. These cranes have been carefully selected to meet the growing demand of the mid-rise building…