New Clearance Anemometer Section on shop.bigfootcrane.com

Abbotsford, British Columbia — Bigfoot Crane Company Inc. is proud to launch a new Clearance section on our specialized e-commerce website, shop.bigfootcrane.com. This section is dedicated to providing our customers with exceptional deals on a variety of overstocked, open-boxed and discontinued anemometers, accessories, and parts at significantly reduced prices. The Clearance section features an extensive […]

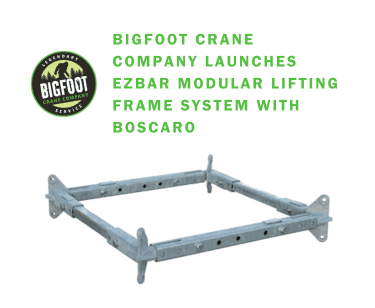

Bigfoot Crane Company Launches EZBar Modular Lifting Frame System

Discover the new EZBar Modular Lifting Frame System by Boscaro, enhancing efficiency and safety in lifting operations.

Brand New Bigfoot Tower Crane Goes Up In North Vancouver

Learn about Bigfoot Crane Company’s first rental of the Liebherr 125 EC-B 6 in North Vancouver, enhancing urban construction with advanced technology.

Bigfoot Crane Company Inc. has been recognized as a Great Place to Work® for the 3rd year in a row

Bigfoot Crane Company Inc. celebrates its 3rd year as a certified Great Place to Work®, emphasizing its commitment to employee care, trust, and integrity in the crane and hoist industry.

Understanding Your Role in Crane Safety

Crane safety is crucial, requiring operator training, planning, risk assessment, and adherence to safety standards like ANSI and OSHA for safe operation.

How Wireless Anemometers Enhance Crane and Lift Safety

Wireless anemometers help enhancing safety in crane and lift operations. We discusses the technology, features, and benefits of these devices, particularly their use in providing real-time, accurate wind data.